When it comes to pressure senstive labels, everything we buy comes with a label. This label contains all of the information we need to help us decide if we want to buy that product. Sometimes, the label is the reason we buy something. The design, the choice of colors, the images, the text, the feel; at times only these elements – regardless of what is inside the packaging – are enough to build up the credibility that makes us buy the product. This is no magic trick: a well-designed, functional, and aesthetically pleasing label communicates, in a non-subtle way, that the work that has gone into making the label has also gone into making the product.

Since you, like me, regularly go shopping for products, there’s a good chance that you have come across pressure sensitive labels. Almost 60 to 80% of all labels used worldwide fall within this category. To put it simply, pressure sensitive labelling is the world’s most used label technology today.

What is a Pressure Sensitive Label?

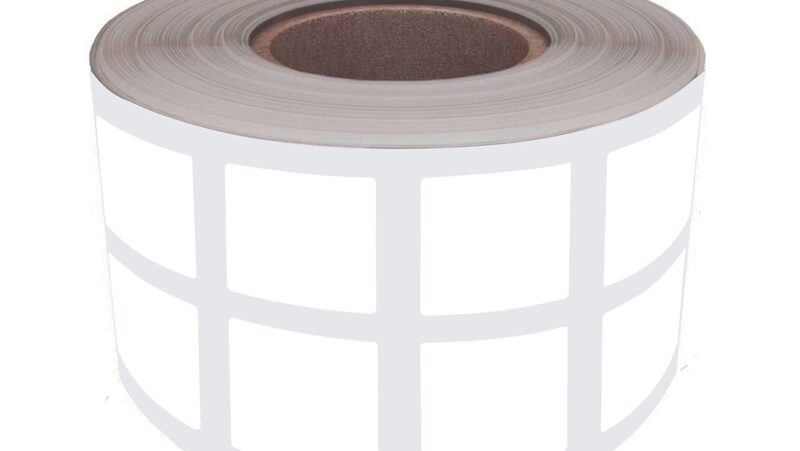

A pressure sensitive label is precisely what is sounds like: a label that is applied to a product using pressure. However, how the label responds to pressure is what makes it unique. You only need to apply pressure to attach the label to the product. This intrinsic quality of pressure sensitive labels makes them easy to use and apply as no heat, water, or solvent is required to activate the label. The labels come in the form of rolls that can be peeled off and applied to a product either by hand or by a machine.

What are the Components of a Pressure Sensitive Label?

Each pressure sensitive label has four components:

- The topcoat or laminate

The topcoat or laminate is applied to protect the label and/or enhance the design. The topcoat can help to protect the label from moisture, sunlight, chemicals, and temperature variations. A topcoat can also be used to give the label a matte, gloss, or semi-gloss finish.

The facestock

The facestock is the core component of the label and determines most of the label’s properties. During label production, it is the facestock to which the ink is applied. Key criteria to consider when selecting the facestock includes the following:

- Cost

- Dispensing/application method

- Environmental conditions

- Abrasion and tear resistance

- Application surface

- Printing technology

- Tactile properties

The materials used for facestock include metallic foil, film, and paper. Paper is the most widely used facestock material. However, the use of polymer film is growing due to properties such as moisture impermeability, durability, mechanical resistance, surface smoothness, color, and strength. The choice of the facestock material will affect both the price and the appearance of the label.

The adhesive

The adhesive is what makes the label stick to the product. The type of adhesive used depends on the application and the environment where the label will be used. Different types of adhesives are available including some that stick permanently, some that are easy to remove, and some that stick despite wet and humid conditions.

The release liner

The release liner is what makes it possible to package the labels in reels that can be easily peeled off. The liner is coated with a special material that enables label removal regardless of the strength of the adhesive used. Materials used for the liner include siliconized paper, film, or any material that does not permit adhesion of the adhesive coating until the label is applied to its final destination.

The properties of a pressure sensitive label are determined by the individual and collective properties of the materials used during manufacture.

What are Some of Pressure Sensitive Label Types?

Now that we know what makes up a pressure sensitive label, it should be easy to understand that using label components with different properties allows the manufacture of labels suited to different applications. Pressure sensitive labels can be categorized into the following broad groups:

Permanent

Hard to remove without actually destroying the label

Removable

Can be removed by carefully prying the label from the surface

Cold temperature

Used for frozen or chilled food and beverages

Specialty

Includes water soluble labels, repulpable labels, high-temperature labels, and re-closable labels.

What are the Advantages of Pressure Sensitive Labels?

Pressure sensitive labels offer many advantages, including but not limited to:

- Ease of application

- Flexibility

- High impact

- High-quality graphics

- Label integrity and durability

- Wide variety of label shapes

- Wide range of print processes

- Variable Information Printed (VIP)

On a more practical level, pressure sensitive labels give a product a unique and professional appearance to enhance its visual appeal. Pressure sensitive labels can be designed in tandem with your logo to help increase brand awareness and recognition, providing significant value.

Other uses for pressure sensitive labels that greatly benefit product manufacturers are as follows:

- Making an impact on consumers

- Sharing product details easily

- Promoting greater sales

What are Some of the Applications for Pressure Sensitive Labels?

Pressure sensitive labels are used for all kinds of products including food and beverage containers, automotive products, industrial products, medical goods, and household products. Because of their versatility, they can be used on virtually any and every kind of product imaginable.

The features of pressure sensitive labels make them uniquely suited to VIP label applications including RFID, serialization, and check weighing.

Can Pressure Sensitive Labels Be Customized?

Yes, it is possible for pressure sensitive labels to be customized. At Coast Label, we have the capability and capacity to produce custom pressure sensitive labels to suit your specific requirements. At our state-of-the-art production facility, we manufacture a wide range of custom pressure sensitive labels including the following:

- PCB labels

- Waterproof labels

- Clear labels

- Cold temperature labels

- Control panel labels

- Tags

- Metal labels

- Nameplates

- Domed labels

We manufacture labels in a variety of colors, shapes, sizes, and materials. If you want it, we can do it!

Why Order Custom Pressure Sensitive Labels from Coast Label?

Our manufacturing operation operates with an ISO 9001:2015 Certified Quality System. We have defined repeatable procedures to ensure consistent quality.

Coast Label is a L.I.F.E.® Certified Facility– proof of our commitment to responsible environmental practices in the production of your order. We recycle all plate-making materials and chemistry as part of our commitment to maintaining the smallest possible environmental footprint.

Customers have been relying on Coast Label to consult with them and provide properly engineered labels that perform throughout the lifecycle of a product or application.

We use our extensive resources to create a solution for your application that combines the correct adhesives, substrates, inks, protective coatings and laminates, and release liner so your labels will perform as required from application through the life of the product to which they are affixed.

For more information about how Coast Label can help you create the perfect pressure sensitive label for your product, contact us for your free proposal!