A customer came to us with a problem that required a very small solution. They already knew that they needed a QR code; however, the size they required made guaranteed scannability and application a challenge.

Therefore, they needed labels small enough to meet their size requirements along with scannability and durability in the industrial environment.

Here’s how we provided them with the solution they needed:

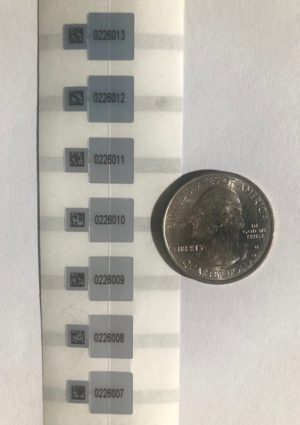

To solve this problem and meet the size requirements, we designed QR code labels that measure at 0.2” x 0.2.” These microlabels offer 100% scannability as part of our TruCheck® ANSI-scoring barcode verification system. This system allows our customers to rest assured that they are receiving a solution that is reliable in design and performance.

Applying microlabels can be challenging, so we attached a numbered application tag to each QR code label, identifying each one for reference and traceability. We then slit the liner along the application tags to make the application process as efficient as possible. The perforation between the application tag and the QR code allows the tag to be seamlessly removed without damaging the label itself.

Key takeaways:

- Due to the size, microlabels require the precision of a reliable manufacturer in order to be effective

- Adding peel tabs and slitting the liner allows for easy, efficient removal of microlabels and prevents potential damage

- A reliable manufacturer will be able to meet unique specifications such as these

The bottom line: The customer received a solution for a unique problem that required precision and reliability. This product is applied to products that enable internal combustion engines to operate on less expensive, cleaner burning fuel, which promotes both energy independence and a cleaner environment. Currently, this customer continues to reorder this solution to guarantee that their products can be accurately labeled and traced throughout its use.