3M™ VHB™ Tapes

Custom Die Cut 3M™ VHB™

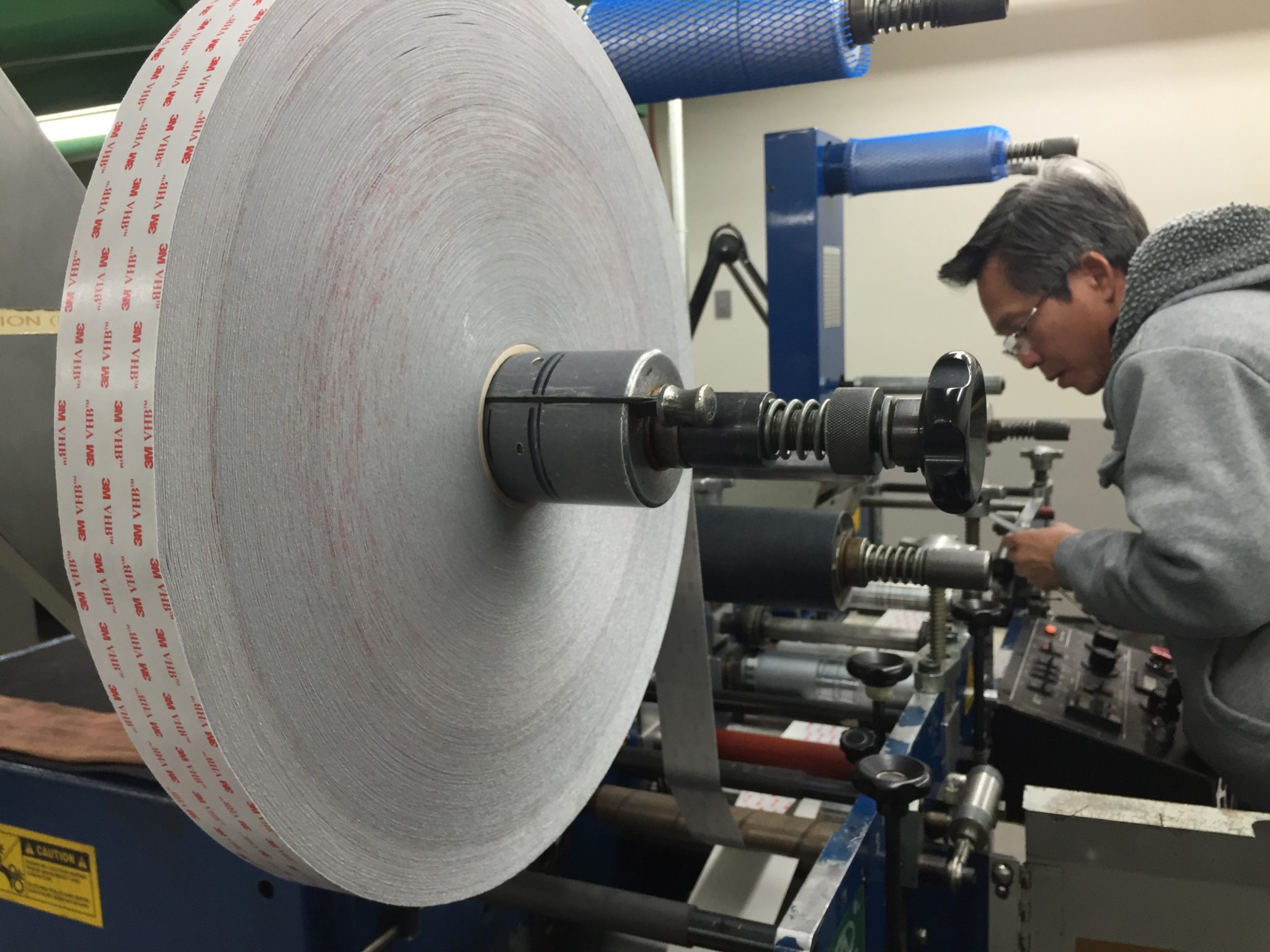

3M™ VHB™ is a high-performance closed-cell foam tape that replaces mechanical fasteners, rivets, welds, screws, and single-purpose dampeners. Because of its powerful capabilities, 3M™ VHB™ has found its way into a wide range of applications and usages. And here at Coast Label, we help you unlock the material’s fullest potential.

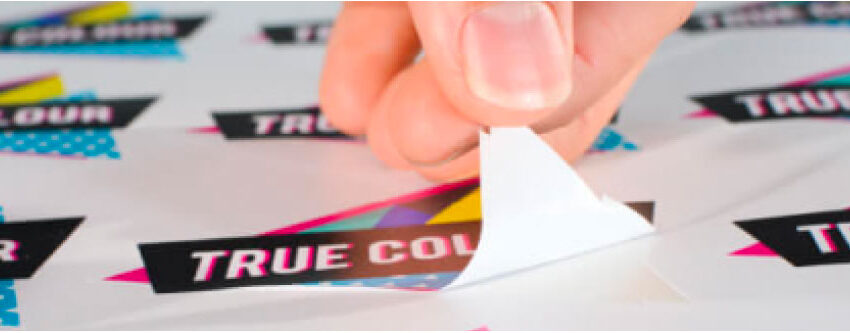

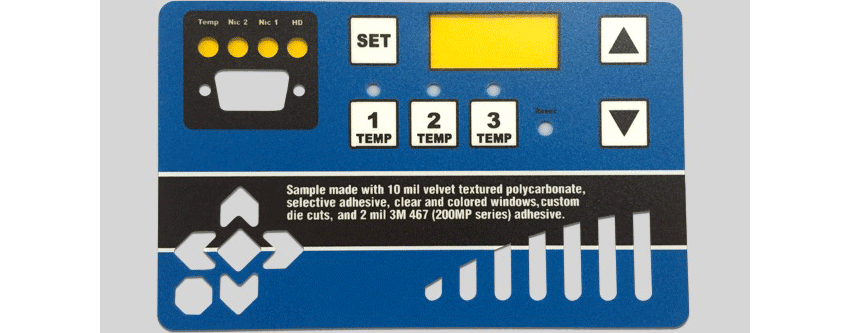

At Coast Label we are able to custom die-cut and finish 3M™ VHB™ tapes turning them into easy-to-apply parts. Our special process introduces an additional silicone release liner onto the 3M™ VHB™ for easier handling, removal, and application. Parts can be generic shapes or customized to fit unusual or tight-fitting spaces.

Saving Time and Money

3M™ VHB™ comes from the factory in self-wound tape roll. For applications where the tape is being applied in long strips including signage and welded strips, this works well. But as parts become smaller, or intricate die cuts are required, you quickly need something more.

At Coast Label we custom die cut various 3M™ VHB™ tapes to fit the tight shapes you require. What’s more, is that many parts can be kiss cut onto silicone release liners instead of just punched out as parts. The end result is easy to store and just as importantly easy to peel parts. No more picking at the edge of the material with your finger nail. Just a time-saving grab and lift as the silicone carrier acts as one easy to use peel tab.

Take full advantage of the multi-purpose acrylic tapes and let the 3M™ VHB™ do all the work for you.

Below is a list of the various 3M™VHB™ materials we offer to our customers. As a select converter for 3M™, our customers can rest assured that they are receiving fresh, genuine material designed for their specific use.

4941 Tape Family

The 4941 family of VHB is manufactured with a multi-purpose acrylic adhesive impregnated in its foam core. This formulation provides excellent adhesion to a broad range of high and medium surface energy substrates including metals, glass, and a wide variety of plastics. The combination of foam strength, conformability, and adhesion makes the 4941 family one of the most capable all-around 3M™ VHB™ Tapes.

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4926

15 (0.4)

300°F/200°F

High

High

Medium

4936

25 (0.6)

300°F/200°F

High

High

Medium

4936F

25 (0.6)

300°F/200°F

High

High

Medium

4941

45 (1.1)

300°F/200°F

High

High

Medium

4941F

45 (1.1)

300°F/200°F

High

High

Medium

4956

62 (1.6)

300°F/200°F

High

High

Medium

4956F

62 (1.6)

300°F/200°F

High

High

Medium

4991

90 (2.3)

250°F/200°F

High

High

Medium

4991B

90 (2.3)

250°F/200°F

High

High

Medium

4919F

25 (0.6)

300°F/200°F

High

High

Medium

4947F

45 (1.1)

300°F/200°F

High

High

Medium

4979F

45 (1.1)

300°F/200°F

High

High

Medium

5952 Tape Family

The 5952 tape family uses a modified acrylic adhesive in concert with a very conformable adhesive foam core. The result? One of the broadest 3M™ VHB™adhesion ranges for materials, including most powder coated paints.

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

5906

6 (0.15)

300°F/250°F

High

High

Medium

5907

8 (0.2)

300°F/250°F

High

High

Medium

5908

10 (0.25)

300°F/250°F

High

High

Medium

5909

12 (0.3)

300°F/250°F

High

High

Medium

5915

16 (0.4)

300°F/250°F

High

High

Medium

5915P

16 (0.4)

300°F/250°F

High

High

Medium

5915WF

16 (0.4)

300°F/250°F

High

High

Medium

5925

25 (0.6)

300°F/250°F

High

High

Medium

5925P

25 (0.6)

300°F/250°F

High

High

Medium

5925WF

25 (0.6)

300°F/250°F

High

High

Medium

5930

32 (0.8)

300°F/250°F

High

High

Medium

5930P

32 (0.8)

300°F/250°F

High

High

Medium

5930WF

32 (0.8)

300°F/250°F

High

High

Medium

5952

45 (1.1)

300°F/250°F

High

High

Medium

5952P

45 (1.1)

300°F/250°F

High

High

Medium

5952WF

45 (1.1)

300°F/250°F

High

High

Medium

5962

62 (1.6)

300°F/250°F

High

High

Medium

5962P

62 (1.6)

300°F/250°F

High

High

Medium

5962WF

62 (1.6)

300°F/250°F

High

High

Medium

5958FR

40 (1.0)

300°F/200°F

High

High

Medium

RP Tape Family

The RP family is the general multi-purpose line of VHB. The adhesive provides adhesion to high and medium surface energy material including metals, glass, and some plastics.

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

RP16

16 (0.4)

250°F/200°F

High

High

Medium

RP16F

16 (0.4)

250°F/200°F

High

High

Medium

RP25

16 (0.4)

250°F/200°F

High

High

Medium

RP25F

16 (0.4)

250°F/200°F

High

High

Medium

RP32

16 (0.4)

250°F/200°F

High

High

Medium

RP32F

16 (0.4)

250°F/200°F

High

High

Medium

RP45

16 (0.4)

250°F/200°F

High

High

Medium

RP45F

16 (0.4)

250°F/200°F

High

High

Medium

RP62

16 (0.4)

250°F/200°F

High

High

Medium

RP62F

16 (0.4)

250°F/200°F

High

High

Medium

4945 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4945

45 (1.1)

300°F/200°F

High

High

Low

4946

45 (1.1)

300°F/200°F

High

High

Low

4945 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4932

25 (0.6)

300°F/200°F

High

High

Low

4952

45 (1.1)

200°F/160°F

High

High

High

4622 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4618

25 (0.6)

250°F/200°F

High

High

Low

4622

45 (1.1)

250°F/200°F

High

High

Low

4624

62 (1.6)

250°F/200°F

High

High

Low

4950 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4914

10 (0.25)

300°F/200°F

High

High

Low

4920

15 (0.4)

300°F/200°F

High

High

Low

4929

25 (0.6)

300°F/200°F

High

High

Low

4930

45 (1.1)

300°F/200°F

High

High

Low

4930F

45 (1.1)

300°F/200°F

High

High

Low

4949

45 (1.1)

300°F/200°F

High

High

Low

4950

45 (1.1)

300°F/200°F

High

High

Low

4955

80 (2.0)

300°F/200°F

High

High

Low

4959

120 (3.0)

400°F/300°F

High

High

Low

4959F

120 (3.0)

400°F/300°F

High

High

Low

4951 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4951

45 (1.1)

300°F/200°F

High

High

Low

4943F

45 (1.1)

300°F/200°F

High

High

Low

4957F

62 (1.6)

300°F/200°F

High

High

Low

4910 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4905

20 (0.5)

300°F/200°F

High

High

Low

4910

40 (1.0)

300°F/200°F

High

High

Low

4611 Tape Family

Product Number

Tape Thickness w/o Liner mils (mm)

Temp Resistance (Short/Long Term)

Solvent Resistance

HSE Relative Adhesion

LSE Relative Adhesion

4646

25 (0.6)

450°F/300°F

High

High

Low

4611

45 (1.1)

450°F/300°F

High

High

Low

4655

62 (1.6)

450°F/300°F

High

High

Low

3M™ VHB™ Application Guide

3M™ VHB™ tape is incredibly strong and durable. Applied correctly it can have a wide range of uses. Here is a quick guide for applying 3M™ VHB™ die cut parts.

1. Clean the Surface

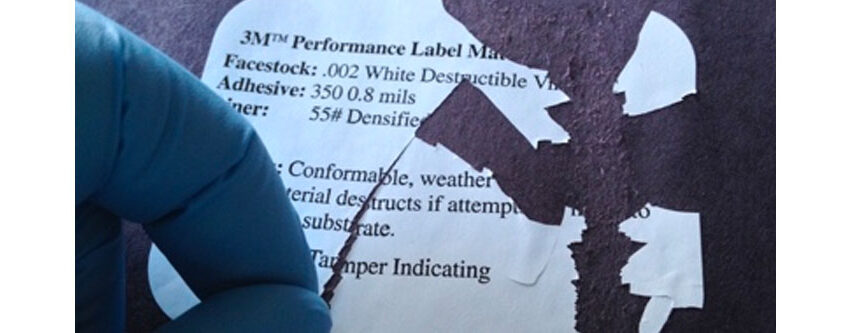

As with all labels, cleaning the surface is the crucial first step of applying 3M™ VHB™ parts. If you don’t clean the surface, it can be difficult for any kind of adhesive to stick–especially long-term. Cleaning the area first removes other substances that could take up much of the adhesive. You can easily remove dust, grease, oil, and other substances with a disposable towel and some kind of solvent. 3M™ recommends using a solution based in isopropanol that’s made up of 70% IPA and 30% water. To remove oil, you should use acetone. Wet your cloth or paper towel with the solution and wipe down the dirty surface. Once you’ve done this, use a dry cloth for a final wipe down.

2. Applying the tape

You can apply die cut 3M™ VHB™ easily by hand. To start, carefully remove from the release liner, exposing one side of the adhesive. Starting at one edge, carefully apply the adhesive part, working from one side to the other, and making sure to apply pressure as consistently as possible.

3. Final Pressure

3M recommends use of a dense J-roller to apply a minimum of 15 lbs of pressure. Regardless, applying pressure at the end is crucial. Wet-out is what people usually call how much pressure you need. Once you’ve done this, you can remove the other protective liner to expose the other side of adhesive.