SELF-LAMINATING LABELS

Applications of Self-Laminating Labels

At Coast Label we create self-laminating labels for applications where hand-written information needs to be protected after being entered in the field or after service operations.

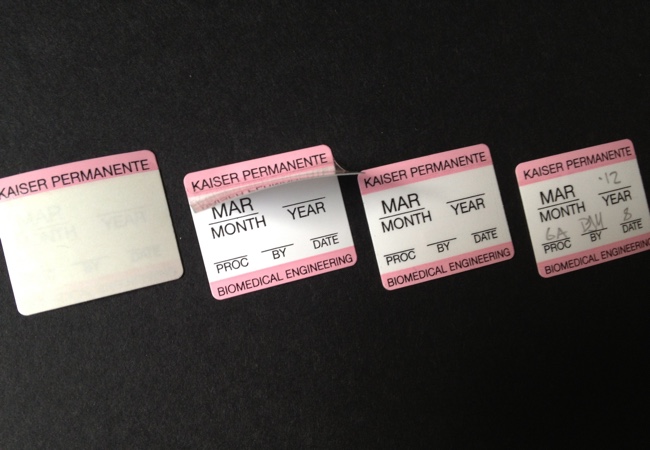

For example, calibration labels are used in everything from preventative maintenance on tools, instruments, and machines to notations in the lab. They also often require handwritten notes or signatures. With Write-n-Seal self-laminating labels, we can provide you the flexibility of quick notation and couple it with long-term durability. Our facestocks are coated to be indelible and non-smudging–accepting handwriting and stamps. And with the ability to seal your information, the writing is protected from tampering.

Coast Label has special expertise in this area and we use custom engineered equipment to produce these labels accurately and efficiently. Our label specialists will work with you to select materials and adhesives so these labels perform well to meet the environmental exposures and longevity requirements of these useful labels in your application.

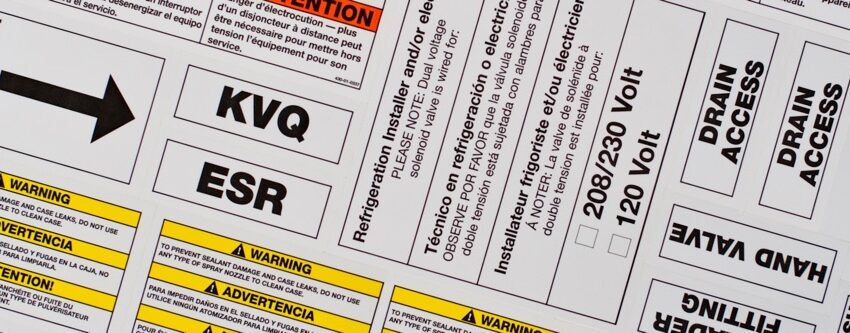

Capabilities of Self-Laminating Labels:

- PGAA Authorization to Print the UL Mark

- UL Classified marks

- UL Listed marks

- Type R labels

- Type L labels

- UL 969

- CSA C22.2 No. 0.15

- UL Recognized Components

Self Laminating Labels Solutions

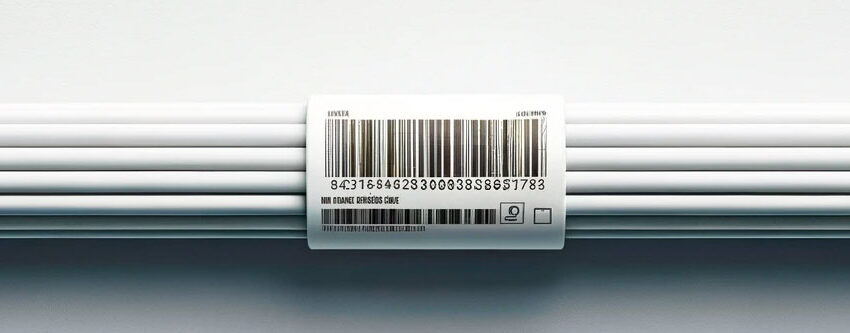

Self-laminating labels are the perfect solution for telecommunication, electrical, and other wire or cable applications. These labels give you the ability to quickly identify voice and data lines during repairs or when problems may arise. Our self-laminating labels adhere to industrial cables, pipes, hoses, conduits, wires, and cables of any nature. Flexible and efficient, we can create an industrial label solution for your needs.

Self Laminating Cable Labels

Self-laminating wire and cable labels are available composed of a variety of different materials to accommodate any number of applications or environments. The structure of the labels ensures that once the label is applied to the wire or cable, it will remain in place without peeling or lifting.

Self-laminating wrap-around labels offer a clear, protective tail-like feature that permanently protects your label. The desired information or text is printed onto the white inscription area of the label. The printed text area is then placed on the cable and the transparent tail of the tag is wrapped around the text. This extra layer of coverage is essential in protecting the text from the elements, including moisture, dust, chemicals, oils, solvents, debris, and extreme cold or hot temperatures. It’s important to note that to achieve the best possible functionality and durability of a self-laminating label, all surfaces to be bonded need to be dry, clean, and completely dust-free.

Designing self-laminating cable labels is a simple process and we are happy to assist you throughout every step of the process.

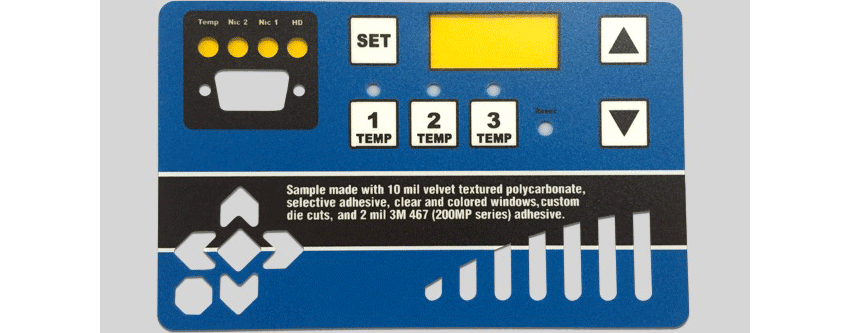

Custom Self Laminating Stickers

Self laminating stickers consist of several layers: the printable layer, a transparent overlay with adhesive and a liner, and an adhesive backing. After the design, barcode, or information is printed, the liner is removed from the transparent overlay. The overlay is then pressed onto the printable layer. The laminating process creates a barrier that shields the printed content from moisture, oils, chemicals, and physical wear and tear so that the sticker remains legible for an extended period.

Self Laminating Vinyl Labels

If you’re looking for a long-lasting label, self laminating vinyl labels are a great option. Vinyl is particularly durable in extreme environments. Self laminating vinyl labels are perfect for outdoor use and can withstand extreme weather, including rain, sunlight, and variable temperatures.

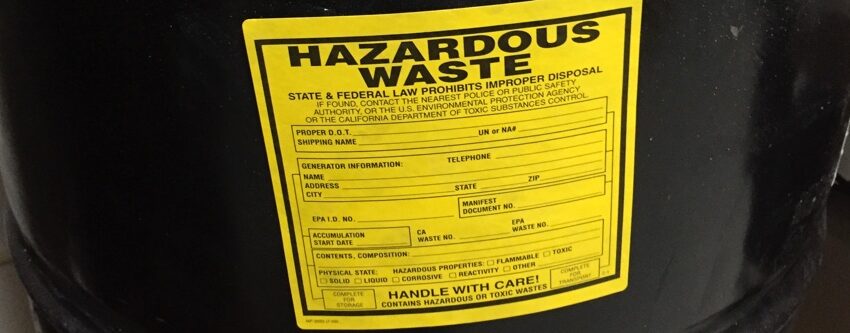

Self laminating vinyl labels are commonly used for the following:

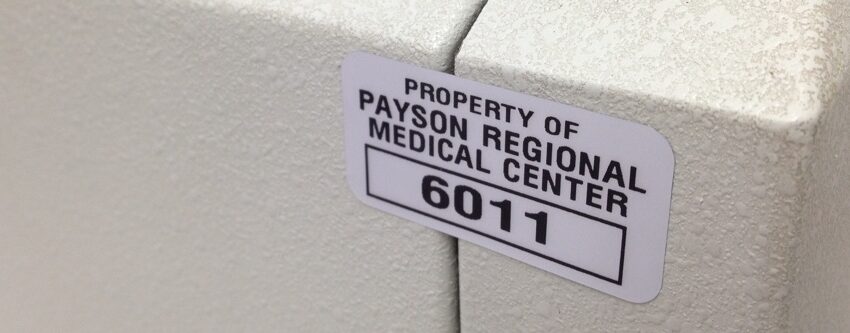

- Asset management: Self laminating vinyl labels can be applied to equipment, machinery, tools, and other assets to provide essential information such as asset ID numbers, maintenance schedules, and safety instructions.

- Product labeling: These labels can be used to label products in industries like manufacturing, electronics, and automotive, where products may be exposed to chemicals and other extreme conditions.

- Healthcare: Laboratory settings often use these labels on test tubes, vials, and equipment. Healthcare facilities use self laminating vinyl labels for patient identification, specimen labeling, and medical equipment marking.

- Warehouse and inventory management: These labels work particularly well for inventory management, warehouse organization, and barcode labeling because the vinyl material is so durable.

Self Laminating Wrap-Around Labels

Self laminating wrap-around labels are particularly useful for labeling cables, wires, and other cylindrical or tubular objects. The printed part of the label is applied to the cable first. Then, the transparent overlay wraps around the cable to protect the printed text or design.

These labels are commonly used in the following applications:

- Cable and wire identification: Wrap-around labels help technicians quickly identify and trace cables and their functions.

- Pipe and tubing marking: Self laminating wrap-around labels can be used for labeling pipes, tubing, and conduits in industrial settings, helping to indicate contents, flow direction, and more.

Self Laminating Laser Labels

If you’re looking for labels you can print in house, self laminating laser labels are designed to work with laser printers. Once printed, the liner of the transparent label is removed and the laminate is pressed onto the printed layer.

Self laminating laser labels are commonly used in the following applications:

- Product labeling: These labels are especially useful for short runs of labels, including special promotions or customized labels.

- Barcode labeling: Self laminating laser labels work particularly well for barcode labels that need to remain scannable and readable over time.

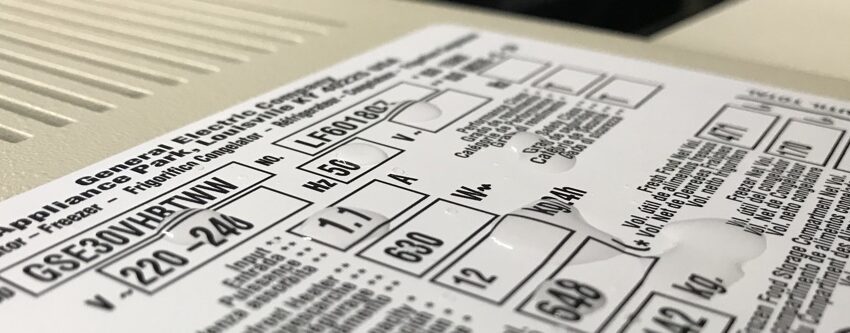

Self Laminating Calibration Labels

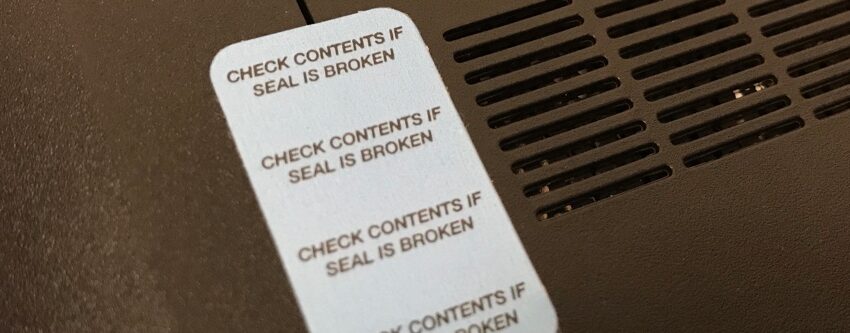

Self laminating calibration labels are used to mark and track equipment, machinery, and instruments that require regular calibration or maintenance. These labels allow you to print the relevant information on the label and then overlaminate it to protect it from harsh conditions. This ensures that the calibration label remains visible and protected over time.

Self laminating calibration labels are commonly used for the following applications:

- Equipment calibration: These labels are commonly used for calibration and maintenance management in industries where equipment accuracy is crucial, such as manufacturing, aerospace, and healthcare.

- Quality control: Self laminating calibration labels help organizations maintain quality control by ensuring that equipment is regularly calibrated and that accurate records are kept.

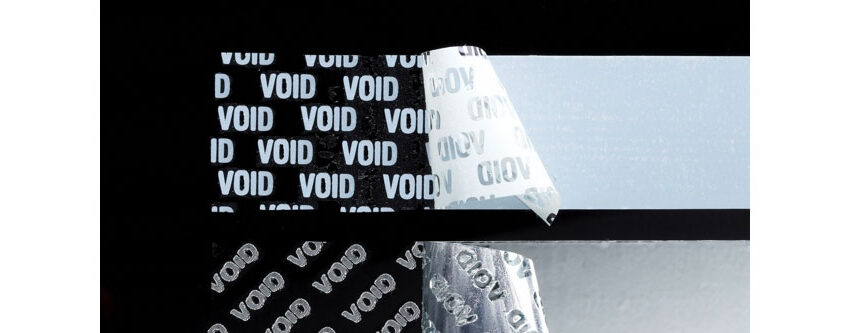

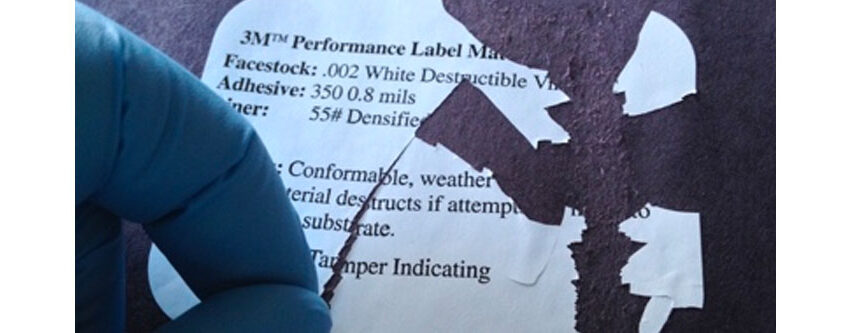

For added security, self laminating calibration labels can include tamper-evident features, such as destructible materials or security slits. This deters unauthorized removal or tampering with calibration information so that equipment remains safe to use.

Self Laminating Hose Labels

Self laminating hose labels are used in various industrial applications to identify hoses, pipes, and tubing. These labels are commonly used in the following applications:

- Industrial: Self laminating hose labels are used in manufacturing facilities, factories, and chemical plants to mark hoses and tubing so that they are used correctly and safely.

- Maintenance: These labels play a crucial role in maintenance and safety procedures. They provide clear identification of hoses, including intended use, maintenance requirements, and safety precautions.

- Compliance: For some industries, hose labels may be required by safety regulations. Using self laminating hose labels ensures that the label remains in place for a long period of time.

- Color coding: Some organizations use color-coded hose labels to quickly identify different types of hoses, such as for water, gas, chemicals, or air.

Self Laminating Tags

For applications where adhesive is not desired or doesn’t function well, self laminating tags are a great option. These tags work just like other self laminating solutions–just without the adhesive backing. Instead, the tags are typically tied by string or other mechanism to the object being marked. Once printed on, the overlay is pressed onto the tag to protect the information.

Custom Self Laminating Labels

There are a number of standard self laminating labels available on the market, but at Coast Label, we don’t just do standard. We specialize in providing custom self laminating labels that are engineered to your exact needs. With our specialized equipment, we can manufacture custom shapes and sizes. That includes tight tolerances, unique shapes, and more.

The Coast Label manufacturing progress is great. They are my go-to label manufacturer for complex printing jobs, including all my medical equipment labels.