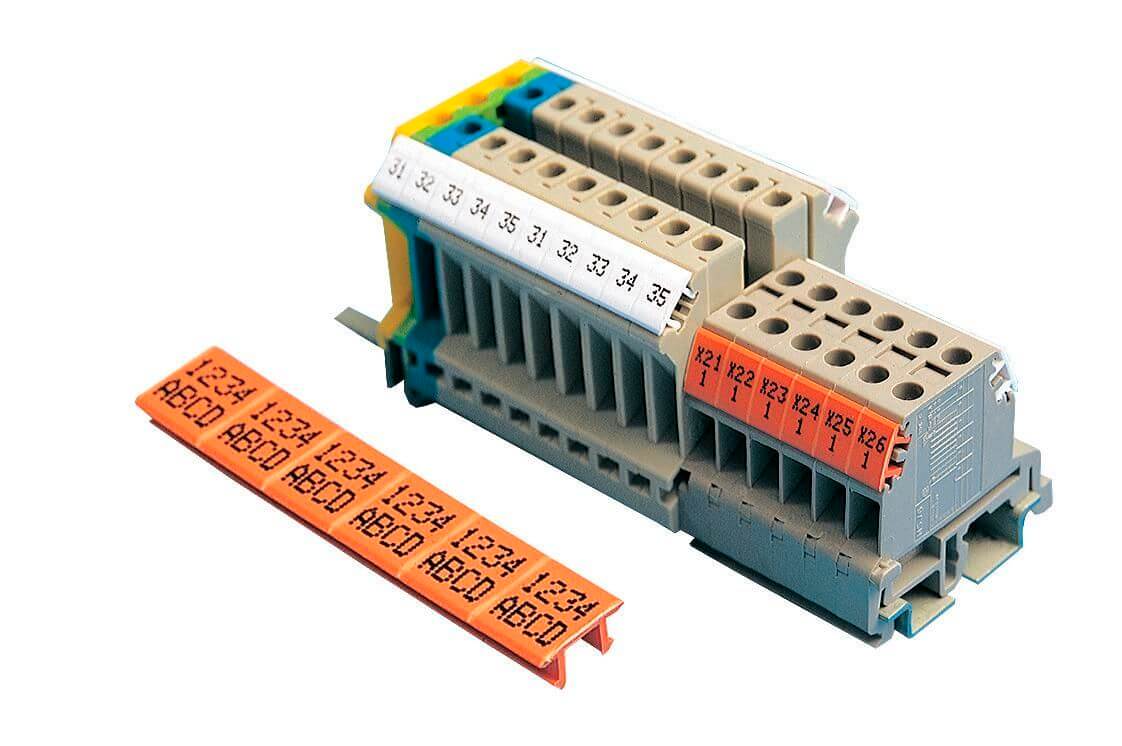

Terminal Block Labels

Terminal block labels play a crucial role in ensuring your electrical system operates seamlessly. These small but indispensable components contribute to the overall organization, safety, and efficiency of complex wiring setups. By labeling the components in your terminal block, you prevent errors while setting up, repairing, and maintaining your electrical system.

Custom Terminal Block Labels

At Coast Label, we understand the unique demands of industrial settings, which is why we specialize in manufacturing custom solutions for various challenges. Our custom terminal block labels are designed to cater specifically to your requirements. From accommodating custom sizes and shapes to offering a spectrum of colors for effective color coding, we tailor our solutions to suit your exact terminal label needs. This level of customization ensures that your labeling system both meets industry standards and also integrates harmoniously with the specific demands of your application.

Custom capabilities of our terminal block labels:

- Custom shapes, including those with tight tolerances

- Custom sizes

- Color matching for practically any color you need

- Weatherproof, heatproof, or waterproof materials for extreme conditions

Terminal Block Label Printing

Terminal block label printing typically requires specialized equipment designed for terminal block labels. To begin, we design our terminal block labels in a dedicated label design software that allows us to input your circuit designations, voltage ratings, and other relevant details. We’ll help you choose the right material for your application, depending on the environmental conditions. Common materials used for terminal block label printing include self-adhesive labels, heat-shrink labels, or polyester labels.

Terminal block labels usually come in a continuous roll. We load the roll into the printer, and once ready, The material is loaded into the printer, and once ready, the printing begins. Once finished, we check the printed labels for quality before shipping them off to you. Our terminal block labels come with a self-adhesive backing for easy application. We also offer terminal block tags, or terminal block marking tags

Terminal Block Tags

In addition to self-adhesive labels, terminal block tags help with the organization of complex wiring systems. Terminal block marking tags provide a visual means to identify wires and connections. They are not adhesive and come in various materials, such as plastic or metal. We offer both custom and standard-sized snap-on terminal block marking tags.

Terminal Block Labeling Standards and Requirements

Terminal block labels help ensure the safety, functionality, and maintenance of electrical systems. While specific requirements may vary based on location and application, some general standards and requirements include:

- Identification information: Labels on terminal blocks should include essential information, such as circuit designations, voltage ratings, current ratings, and other relevant details.

- Identification information: Labels on terminal blocks should include essential information, such as circuit designations, voltage ratings, current ratings, and other relevant details.

- Durability: Another important requirement for terminal block tags and markers is durability. These labels need to be durable enough to withstand the environment conditions of the installation site, including extreme temperature, the presence of moisture, or exposure to chemicals.

- Legibility: Terminal block labels need to be printed in clear, legible fonts that are large enough to be easily read. Proper font and size help with quick identification and reduce the chance of errors.

- Compliance with regulations: Depending on both your industry and location, you may need to follow specific standards set by organizations like the IEC, NEMA, or the IEEE. Compliance with these standards ensures consistency and safety.

- Placement: Labels should be placed for easy visibility and accessibility during installation, maintenance, and troubleshooting.

- Maintenance procedures: Establishing procedures for updating and maintaining labels is crucial. As systems evolve or components are replaced, terminal block labels need to be updated accordingly so their information is accurate.

By adhering to industry standards and regulations, your organization will ensure that your electrical system is not only compliant but also optimized for efficiency and safety.

At Coast Label, we can help you design custom terminal block labels that keep you compliant and safe. We’ll work with you one on one to find the right solution for labeling your complex electrical system.