When designing your product packaging, you might be considering using colors other than a black-on-white barcode. While it’s possible to use different color combinations, you do need to be careful to ensure your barcodes will scan every time. Barcodes that won’t scan waste valuable time and money.

Wondering about white barcodes and other barcode colors? Read our guide to learn everything you need to know when choosing barcode color combinations.

What Is A Data Matrix Barcode?

Barcode Colors

To understand which color barcodes are best, it’s important to know how barcode scanners work. Typical barcode scanners shine a red light at the barcode and read the amount of light that is reflected back. White is highly reflective, while black absorbs much of the light. Light and dark bars are arranged in certain patterns to represent numbers. Because both the white gaps and the black bars are part of the code, the contrast between the two is essential. To be scannable, a barcode needs to have a Print Contrast Signal (PCS) of 80% or higher.

Black-on-white barcodes are the most common and reliable color combination. The high contrast between black and white makes the code easily read by any barcode scanner. However, depending on the color of your packaging or label, you may want or need to choose a different combination.

When choosing barcode colors, you’ll want to make sure the PCS between the colors is at least 80%. Colors that are too similar won’t scan. Additionally, watch out for too much reflection. Shiny material can obscure the reflection of the dark and light lines, rendering the barcode unscannable.

Can I Use a Red Barcode?

If you’re tempted to use a red barcode on white, think again. A red-on-white barcode is completely unscannable. Typical scanners use either red or infrared light. The light is highly reflected by red print, and the scanner reads this as white. So if your barcode has red bars on a white background, there will be no contrast between the colors and the barcode won’t scan.

The Best Color Barcode Combinations

As mentioned above, a black-on-white barcode is the most optimal barcode color combination. The high PCS means the code will scan every time. Here are some other barcode color combinations that work well:

- Green on white

- Blue on white

- Brown on white

- Black on yellow

- Green on yellow

- Blue on yellow

- Brown on yellow

- Black on orange

- Green on orange

- Blue on orange

- Brown on orange

- Black on red

- Green on red

- Blue on red

- Brown on red

The contrast between these color combinations is high, making the scanner able to read the code. Although red bars should never be used to create a barcode, a red background works much the same as a white background would work.

The Worst Color Barcode Combinations

When designing your barcode, you’ll want to watch out for certain color combinations. The absolute worst barcode color is red on white, but there are other problematic color combinations to be aware of.

- Inverted colors: Barcodes work best when the background is light and the bars are dark. When you invert the colors so that the background is black and the bars are white, the barcode won’t scan. If you do need to print a barcode on black packaging, print the gaps in white so that the color combination works as it should.

- No contrast: If you print light bars over a light background, or dark bars over a dark background, your barcode will not scan. Remember, you need to have a significant contrast between the colors in order to create a scannable barcode.

- Black on green or blue: Barcodes read both green and blue colors as black because the red light is absorbed rather than reflected. Black on green or blue barcodes are therefore unscannable and should be avoided.

- Yellow or orange on white: Just like red on white barcodes, yellow or orange on white barcodes are unscannable. The yellow and orange bars reflect too much of the red light and read as white.

Barcode Alternatives

Although barcodes are the most common way to quickly scan inventory, they aren’t the only solution. Data matrix codes are a kind of 2D barcode that can encode much more information than a standard 1D barcode. Because data matrix code scanners only need a 20% contrast to read a code, you have more options for customizing your code with colors. As long as you use contrasting colors and avoid inverting the colors, you should be able to create a colorful data matrix code that scans quickly and reliably.

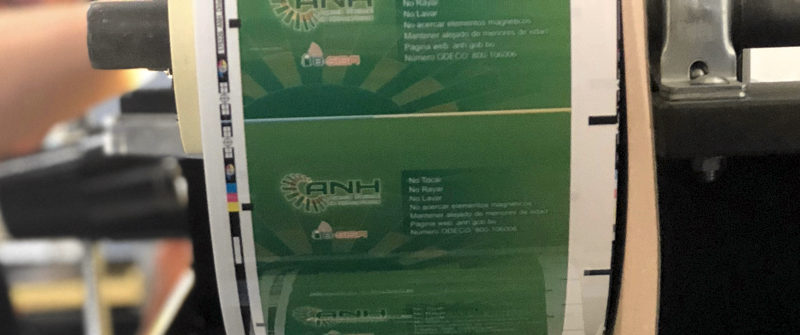

Reliable White Barcode and Color Barcode Labels

Whether you need white barcode labels or colorful data matrix code labels, you can count on Coast Label. Using the TruCheck barcode verification system, we’ll make sure your barcode labels scan every time. We use only the highest quality materials to ensure that your labels stay put and remain scannable. Contact Coast Label today to see the Coast difference.