Managing a warehouse is a big task, but luckily there are a number of warehouse storage systems to choose from. Finding the right storage system can help you save space and improve your inventory management.

In this guide to warehouse storage systems, we’ll discuss different types of storage systems to help you find one that will work best for your facility. Because labeling is so integral to an organized warehouse, we’ll also discuss some of the labels used in warehouse storage solutions.

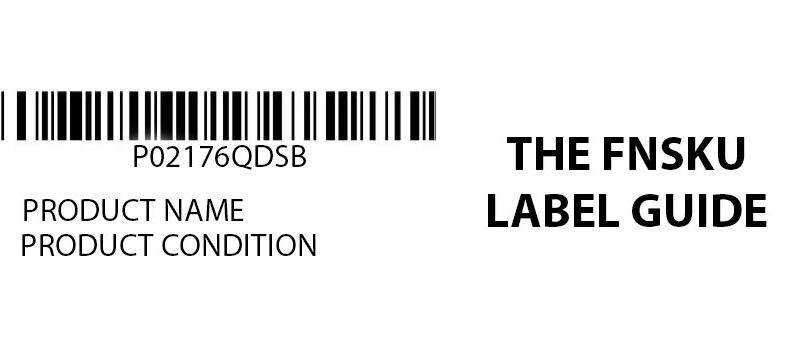

LPN Labels for Warehouse Logistics

What Is A Warehouse Storage System?

A warehouse storage system is a combination of methods and equipment used to organize, store, and manage products within a warehouse. These systems help you maximize space, improve inventory management, and retrieve goods more efficiently. Setting up a warehouse storage system can be expensive, but it’s worth the effort and money to find the right one.

Some of the benefits of warehouse storage systems include:

- Optimized use of space: Storage systems use a combination of both vertical and horizontal space to store inventory. This minimizes wasted space and allows your facility to store more.

- Better inventory management: Organized storage systems can help your business categorize, locate, and track inventory more accurately. This leads to better inventory control, easier stock counts, and timely reordering of products.

- Increased productivity: Many warehouse storage systems make picking and replenishing processes go more quickly for faster order fulfillment.

Supplement Warehouse Racking System

Supplement warehouse racking systems are specialized storage solutions designed to efficiently store dietary supplements, vitamins, and other health products. Because these products are sensitive to environmental conditions, special care must be taken to properly store and rotate them. In fact, both the FDA and the cGMP (Current Good Manufacturing Processes) have regulations that must be followed when storing supplements.

Some of the key types of racking systems used in supplement warehouses include:

- Selective pallet racking: Larger pallets of supplements are stored to allow direct access to pallets. This system works well for bulk supplement storage.

- Flow racking: Flow racking uses inclined racks with rollers to allow products to flow from the back to the front. When an item is picked from the front, the next one moves forward to ensure first-in, first-out inventory management.

- Temperature-controlled racking: Some supplements must be kept in temperature-controlled environments. These types of racks are often combined with cold storage solutions to keep the temperature precise.

In order to comply with the FDA, your supplement warehouse racking system must involve regular monitoring and recording of environmental conditions, sanitation efforts, lot tracking systems, and quality control measures. Durable warehouse labels from Coast Label can be used as part of your supplement racking system to track batches, lots, expiration dates, and more.

Storage Control Sampling System

A storage control sampling system is a quality control method used in warehouses and storage facilities. This system involves taking samples from a batch or lot of stored items at regular intervals and testing them. The food and drink, pharmaceutical, and chemical industries in particular rely on this kind of system to identify potential problems like spoilage and stay compliant with regulations.

Key elements of a storage control sampling system include:

- A set procedure for taking samples that defines how often samples should be taken, and how the samples should be handled.

- A sampling plan outlines how many samples will be taken, what percentage of total stock, and which testing method will be used.

- Samples are tested for quality attributes, such as potency for pharmaceuticals or spoilage for food products.

- Quality control labels can be used as part of the storage control sampling system. These labels allow you to record testing dates, batch or lot numbers, as well as whether the products passed or failed inspection.

Warehouse Storage Solutions

When it comes to warehouse storage solutions, there’s no one-size-fits-all system. Some warehouse storage systems are small and simple, and some involve high-tech equipment. The right one for your organization will depend on the types of products you’re storing and the amount of space you have. Here’s a rundown of some of the most common types of warehouse storage systems.

Static Shelving

Static shelving is meant for smaller items that are not stored on a pallet. Shelves are mounted in place to create fixed aisles, and items are stored in bins. Static shelves do not work with forklifts, which means these types of shelves are best used on lightweight products that need to be hand-picked and replenished.

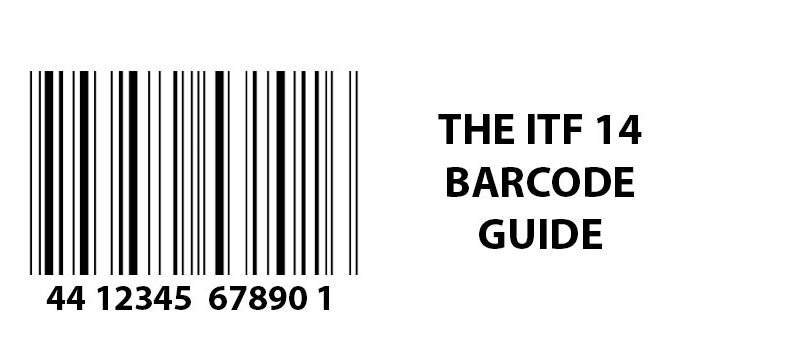

Barcode labels are commonly used to mark both the products and the shelves. When picking for an order, employees can scan the shelf and grab the product. If used with an inventory management system, information about the order can be updated automatically. Other types of labels used in static shelving include bin labels, location labels, and floor labels.

Mobile Shelving

Mobile shelving is a space-efficient warehouse storage system where shelving units are mounted on tracks. This allows them to move side-to-side to create aisles when needed. Mobile shelving is best used in environments with limited space.

Like static shelving, mobile shelving relies on barcode labels to track the picking and restocking of products. Hanging labels or placards can be used to mark large sections or areas in the warehouse, and RFID labels can be used to automatically track the movement of inventory.

Pallet Racking

Pallet racking is designed for storing palletized goods. It consists of horizontal beams and vertical frames that allow pallets to be stacked vertically. Pallets are stocked or picked with a forklift. There are a number of different types of pallet racking systems, including selective, drive-in, push-back, and pallet flow racking.

Pallet labels are commonly used in pallet racking systems. Pallet labels contain product information, barcodes, or RFID tags to track the contents of the pallet. The labels may also include handling information, such as “Fragile” or “Do Not Stack.”

Multi-tier Racking

Multi-tier racking maximizes vertical space by creating multiple levels of shelving or racking. This system allows for the storage of a large quantity of smaller items across different tiers. It works especially well in warehouses with high ceilings. With multi-tier racking, you can gain access to all levels through staircases, walkways, or lifts. As your needs change, you can add or take away tiers.

Common types of labels used on multi-tier racking include barcode labels, bin labels, RFID labels, and reflective long-range labels.

Mezzanine Flooring

If your warehouse has high ceilings, mezzanine flooring is one warehouse storage solution you might consider. Mezzanine flooring is a raised platform that’s installed within a warehouse to create more storage and work areas. The platform utilizes vertical space without changing the building’s footprint. Mezzanine flooring is often more expensive than the other warehouse storage systems on this list, but it also gives you more customization options.

Types of labels used with mezzanine flooring include barcode labels, bin labels, RFID labels, pallet labels, and more. Color coded labels can be used to improve organization. For example, red labels could be placed on products meant to be stored on the mezzanine while green labels would indicate first-floor placement.

Wire Partitions

Wire partitions are durable, modular barriers made from steel wire mesh panels. They create a cage-like space that can be moved as the needs of the warehouse change. Wire partitions are easy to assemble and customize. They also prevent unauthorized access to valuable or sensitive items, and they’re also one of the most cost-effective warehouse storage systems.

If using wire partitions for valuable products, tamper-evident labels may be a good choice. These labels cannot be removed without leaving behind evidence. Tamper-evident labels increase the security on sensitive products.

Best Warehouse Storage System

Finding the right warehouse storage solution can be tricky. All warehouse storage systems have pros and cons. When it comes down to it, the right system for your facility depends on your storage space as well as the types of products you’re storing.

If you’re looking for labels to help improve your warehouse processes, look no further than Coast Label. We manufacture custom labels designed to suit your unique needs, including barcode labels, reflective labels, tamper-evident labels, and more. Contact us today to see what Coast Label can do for you.