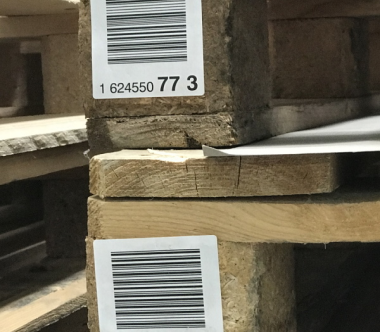

Custom Pallet Labels

In the fast-paced world of supply chain management and logistics, one humble but powerful tool helps you stay on track: pallet labels. These adhesive tags ensure a seamless flow of goods from the manufacturers to consumers. As products move through warehouses, distribution centers, and transportation networks, pallet labels are essential for tracing and tracking products.

Whether you’re moving pallets through your warehouse or transporting them across state lines, pallet labels can help you save money and increase efficiency. Read on to learn more about the mighty pallet label and how it can benefit your operations. We can improve your process by making custom pallet racking labels and pallet label stickers specific to your needs.

What Are They?

Just as the name implies, pallet labels and pallet label stickers are labels applied to pallets. These labels serve several purposes, including providing tracking, shipping, and content information. Although simple, pallet labels are integral to the smooth and efficient operation of logistics, transportation, and warehouse management.

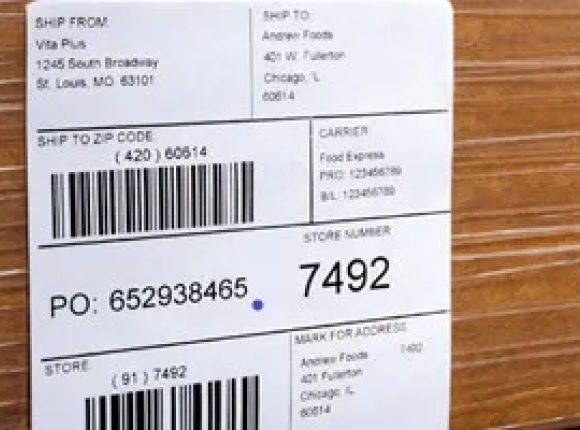

Here are some common elements found on pallet labels:

- Shipping information: Shipping information identifies who sent the pallet and where it needs to be delivered.

- Pallet contents: A description of the items or products inside the pallet tells handlers what is in the pallet. This might include product names, SKUs, quantity, and other relevant information.

- Barcodes: Barcodes make it easy to automate the tracking and sorting of pallets.

- Handling instructions: Special instructions related to handling the pallet may be included. For example, pallet labels can indicate if the goods are fragile or require a specific temperature.

- Weight and dimension: The weight and dimensions of the pallet are often included to help logistics personnel plan for space and weight distribution during loading and unloading.

- Country of origin: If the goods are being imported or exported, the country of origin can be indicated on the pallet label for customs processing.

- Hazardous material indicators: Pallets containing hazardous materials require specific symbols or labels to indicate the nature of the hazards.

- Tracking information: Some pallet labels include tracking numbers that allow shippers and recipients to monitor the real-time progress of the shipment.

Benefits of Pallet Labels

Pallet labels and pallet label stickers are extremely versatile and can be used in a number of ways that benefit you. Here are some of the key benefits of using pallet labels in your supply chain operations:

- Compliance: Depending on the industry you’re in, you may have certain industry regulations to follow. For example, the pharmaceutical industry requires pallets to be labeled with manufacturing dates, lot numbers, and/or expiration dates. Pallet labels can help you comply with these important standards.

- Improved inventory management: With the contents of the pallet clearly identified, warehouse staff can easily identify and track inventory. This in turn reduces the number of errors made and ensures accurate stock management.

- Accurate order fulfillment: Today’s customer expects their orders to be fulfilled quickly and accurately. Pallet labels make order picking and fulfillment faster and more precise.

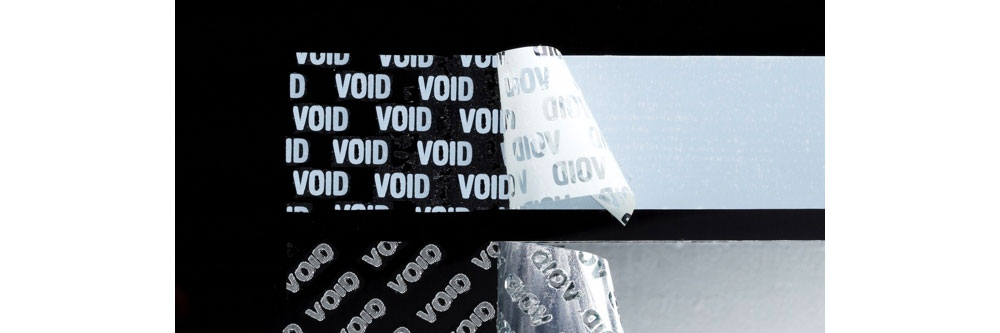

- Better traceability: Many pallet labels contain barcodes, which enable the seamless tracking of shipments. This traceability minimizes the risk of loss or theft and allows for real-time monitoring of delivery progress.

- Optimize loading: Pallet labels that display weight and dimensions help with better load planning so that shipments are properly balanced and loaded. This maximizes transportation capacity and minimizes the risk of damage during transit.

How Pallet Labels Work

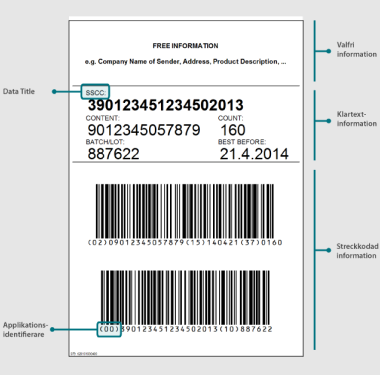

Pallet labels work hand in hand with your warehouse management system to increase efficiency and accuracy in your supply chain operations. First, individual products and goods are given identification numbers. When these products are grouped together, they create a secondary package called a carton. A pallet contains groups of cartons. Most pallets are wrapped in shrink wrap to keep the goods in place. After the shrink wrap is applied, a pallet label is placed on the pallet where it can be clearly read. The pallet label contains key information for tracking all of the goods contained on the pallet.

Many pallet labels include barcodes, which help improve accuracy and efficiency in your supply chain. Warehouse personnel and logistics workers use scanners to read the barcodes quickly. The scanned data is then captured and processed by your warehouse management system or other tracking software. By scanning pallet labels at each step of the supply chain, your company can better track the location of the pallet and its goods. Because pallets contain many products, a large number of goods can be tracked with the scan of one pallet label.

Transport Labels

Transport labels are similar to pallet labels, but they aren’t exactly the same thing. Transport labels are used specifically during transportation. They can be used on individual packages or entire shipments. Much like pallet labels, transport labels aid in automating the sorting and tracking of goods being transported.

Pallet Rack Labels

Pallet rack labels are essential identification tags used in warehouse racking systems to organize and manage inventory. These labels, which may include SKU numbers, product descriptions, barcodes, and location codes, help you quickly identify and locate items, improving efficiency and accuracy. They come in various forms such as adhesive labels, magnetic labels, hanging tags, and clip-on holders, all designed to withstand warehouse conditions like moisture, dust, and temperature fluctuations. Many labels incorporate barcodes or RFID tags for automated scanning and inventory tracking, reducing human error. Customizable options like color-coding and different sizes allow for tailored organizational needs.

By using pallet rack labels, warehouses can streamline inventory management, improve order fulfillment speed, and maintain accurate stock control. Easy to install and replace, these labels offer flexibility as inventory changes or storage needs evolve. Overall, they significantly enhance the efficiency of warehouse operations, ensuring a well-organized and smoothly functioning storage environment.

Best Surfaces for Pallet Labels

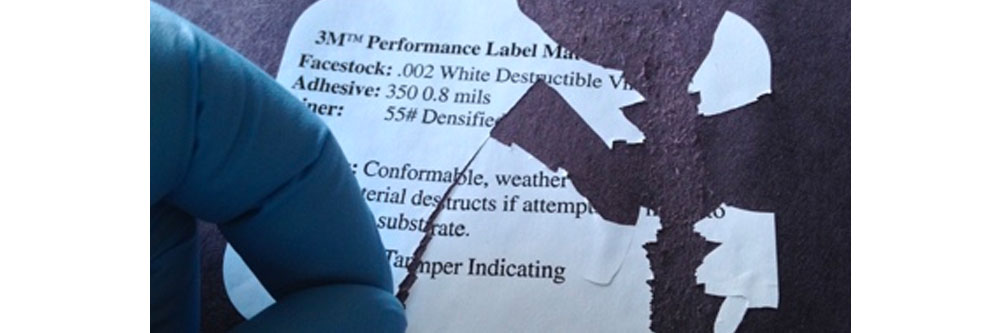

Pallet labels need to be durable to stay put during all stages of the supply chain. The best surfaces for pallet labels will depend on the type of adhesive and material your labels are made from. Some surfaces, such as wood and plastic, can be harder to secure labels to. In these cases, a more durable adhesive can be used.

Choosing the right company to manufacture your pallet labels can make all the difference. At Coast Label, we’ll help you choose the right combination of adhesives and materials so your labels stay put and legible throughout the supply chain. We can manufacture labels that adhere to wood, plastic, film, cardboard, metal, and more.