CUSTOM SAFETY LABELS

Whether you’re in construction or food service, you know how important it is to keep your employees safe. One of the simplest ways to promote a safe work environment is with custom safety labels. These labels convey important safety information and warnings. Whether you’re looking to enhance safety protocols, comply with regulations, or simply raise awareness, custom safety labels play a key role.

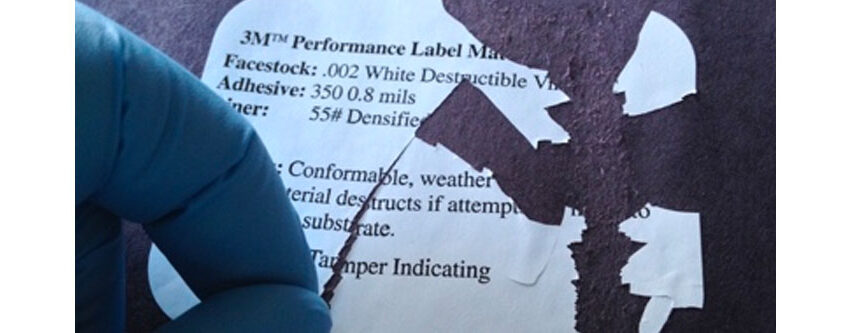

At Coast Label, we understand how vital it is for safety labels to withstand the extremes of an industrial environment. That’s why we use only the best materials to manufacture custom safety labels. Whether your labels will be exposed to extreme temperatures, chemical exposure, or water exposure, we’ll help you choose the right materials to create a truly durable safety label.

Best Safety Label Uses

Custom safety labels are used globally to warn of hazards, provide safe handling instructions, and prevent accidents. Here are some of the best safety label uses:

- Hazard identification: Safety labels are commonly used to identify and communicate potential hazards in the workplace. From labeling chemical containers to electrical panels, safety labels help people quickly recognize dangers and take appropriate precautions:

- Risk mitigation: Safety labels provide crucial information about how to mitigate risks associated with various hazards. They may include instructions for safe handling, operation, or use of equipment, as well as precautions to prevent accidents.

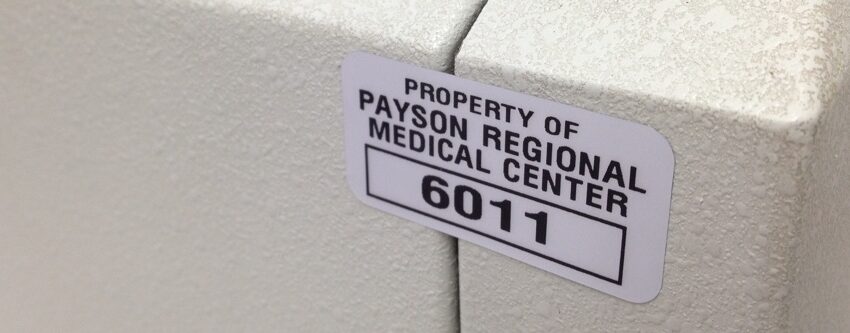

- Equipment identification: Custom safety labels identify different types of equipment and machinery in the workplace. Clear labeling ensures that employees and visitors can easily recognize potential risks as well as safely operate the equipment.

- Compliance: Many industries are subject to regulations and standards regarding safety labeling, such as OSHA, ANSI, or the NEC. Safety labels help companies comply with the requirements by providing necessary warnings, instructions, and information about hazards.

- Training and education: Safety labels play a role in training and educating employees about workplace safety. By clearly conveying hazards and safety measures, custom safety labels help raise awareness and promote safe practices among workers.

- Emergency response: In the event of an emergency, safety labels provide essential information for first responders and emergency personnel. They may include details about emergency shutdown procedures, evacuation routes, emergency contact numbers, and other critical information during an emergency.

- Liability protection: Properly labeled equipment and products can protect you from liability in the event of an accident. Safety labels demonstrate your commitment to safety and provide evidence that you took reasonable steps to warn of potential hazards.

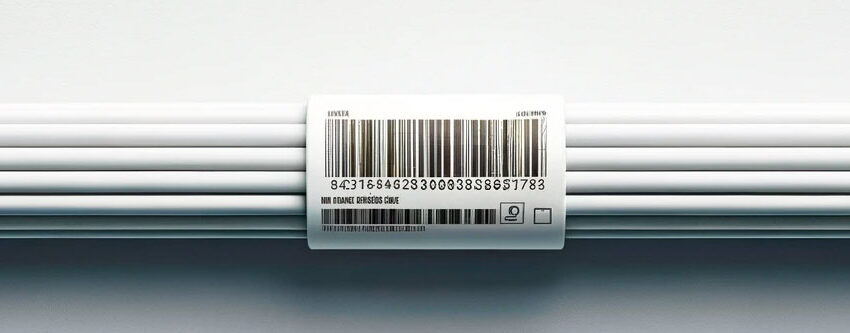

- Tracking maintenance: Custom safety labels can be used to track maintenance and ensure equipment is being properly cared for. Whenever maintenance is performed on the equipment, the maintenance personnel document the information on the safety label or scan a barcode that will automatically update the records. Properly maintaining equipment keeps it working longer and ensures compliance with industry regulations.

Types of Safety Labels

While custom safety labels all have the same end goal of keeping employees safe, each type of safety label requires different elements. It’s important to follow industry standards for what to include as well as for materials used. For example, chemical safety labels need to be resistant to chemical exposure while outdoor equipment labels may need to be UV-resistant and waterproof.

Here are some of the types of safety labels we manufacture:

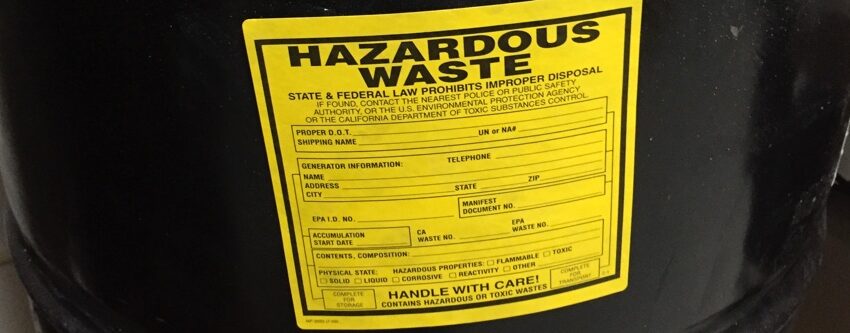

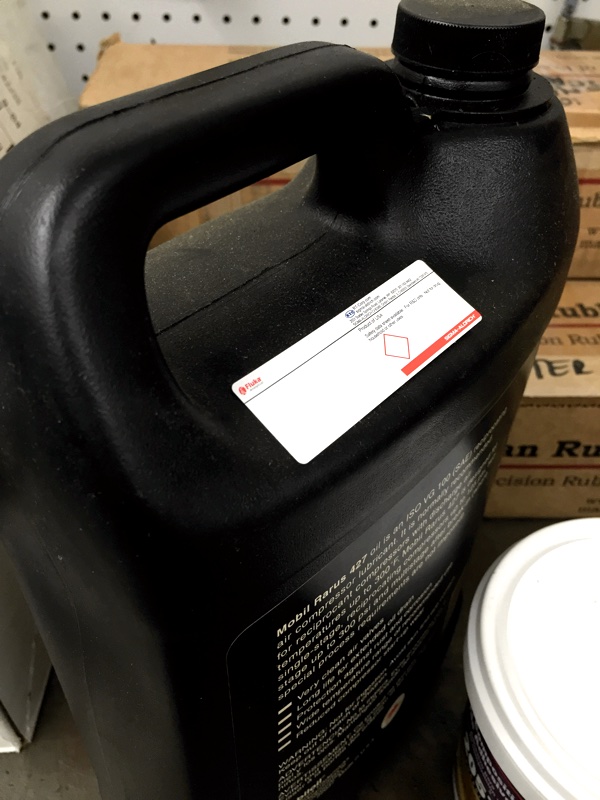

Chemical Safety Labels

Chemical safety labels are designed to communicate the potential hazards of a chemical. These labels are a crucial component of hazard communication in workplaces where chemicals are used or stored. Per OSHA’s HazCom, chemicals must be labeled according to the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) standards. It’s also important that chemical safety labels are made from materials that can handle chemical exposure.

Some key elements that must be included on these labels include:

- The chemical name

- A signal word (either “Danger” or “Warning,” depending on the severity of the hazard)

- A pictogram, which visually represents the type of hazard, such as flammability, toxicity, or corrosiveness

- A hazard statement, such as “May cause skin irritation”

- Precautionary statements, which promote the safe handling and use of chemicals

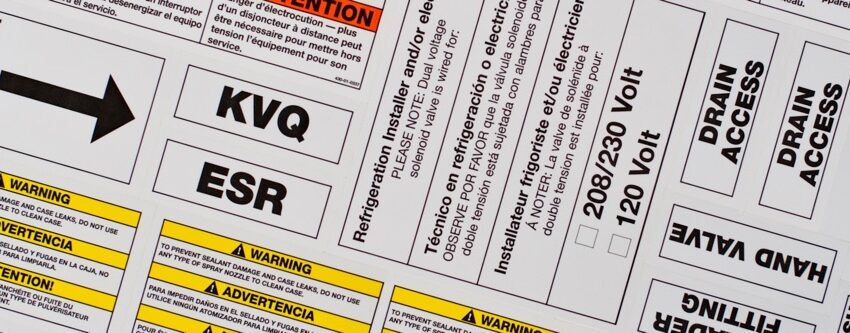

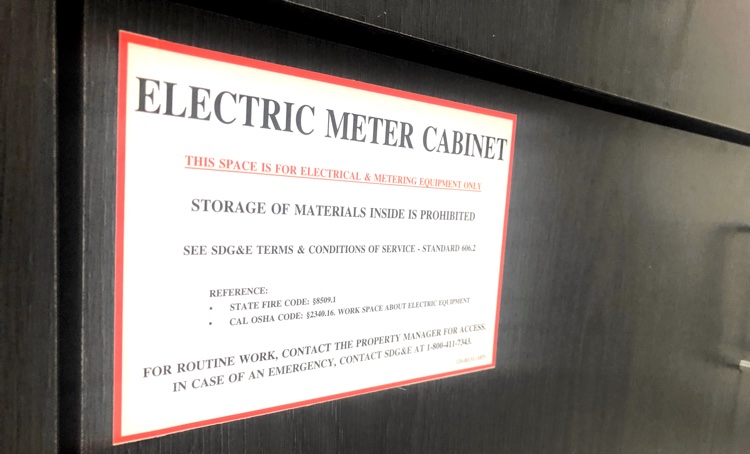

Electrical Safety Labels

Electrical safety labels are essential for warning employees about electrical hazards. These labels indicate the presence of electrical equipment, voltage levels, and safety precautions. Electrical labels help mitigate risk of electric shock, electrical fires, or arc flash incidents. Electrical hazards must typically be labeled according to the National Electrical Code. These labels are usually meant to be permanent and must be made from durable materials.

Some key components of electrical safety labels include:

- Voltage rating of the equipment or electrical system

- Warning symbols, such as lightning bolts or hazard triangles

- Safety instructions and precautions for operating the equipment

- Arc flash hazard information

- Identification of equipment, components, and circuits

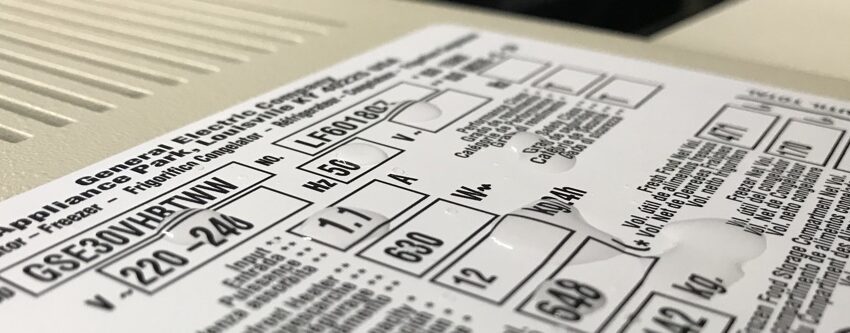

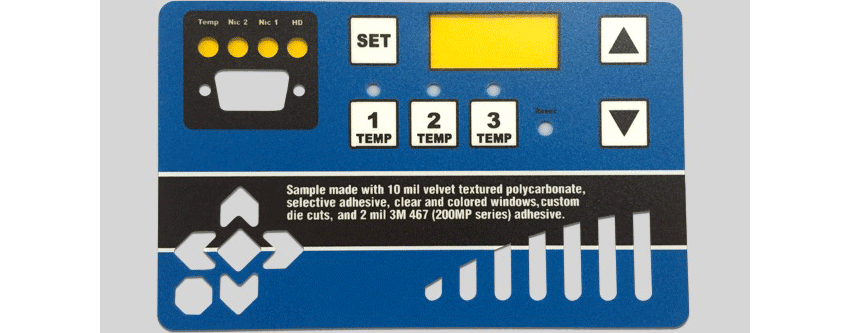

Machine Safety Labels

Machine safety labels are used to alert employees about the risks associated with operating machinery. They often include warnings about moving parts, pinch points, hot surfaces, and other potential hazards. These labels play a crucial role in preventing accidents and ensuring workplace safety. Because machine safety labels are often subjected to extreme environments, abrasion, or outdoor weather, they must be durable enough to handle these extremes.

Machine safety labels often include:

- Safety instructions regarding operation and use of the machine

- Warning messages to alert employees to potential dangers

- Emergency information, such as in the event of a machine malfunction

- Machine identification with the VIN or serial number

- Maintenance records

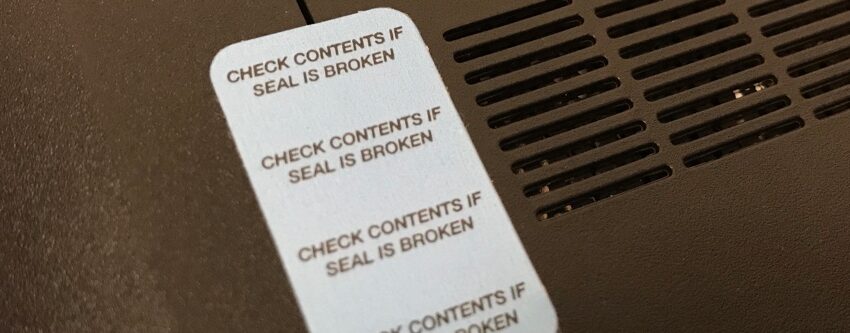

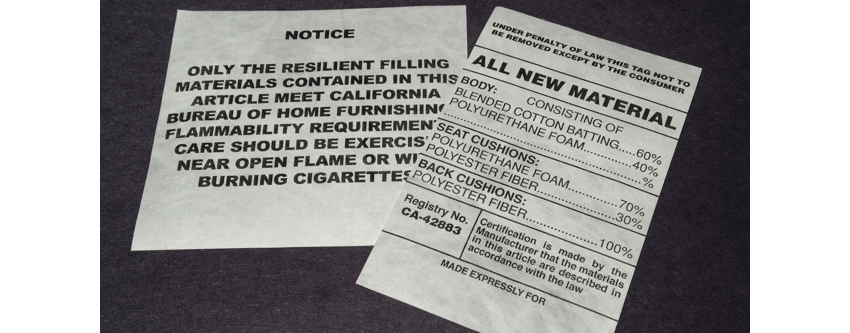

Safety Warning Labels

Safety warning labels can encompass a wide range of hazards and precautions. These may include warnings about slipping hazards, confined spaces, high noise levels, or any other potential risks present in the workplace. They can help you stay more organized, remain compliant with industry regulations, and mitigate the risk of accidents. Depending on the industry you’re in, you may need to follow OSHA, ANSI, or other labeling guidelines.

Some types of safety warning labels you might need include:

- Safety equipment location labels

- Pipe markings

- PPE reminders

- Shut off location labels

- Wet surface labels

Whether you need chemical safety labels or safety warning labels, Coast Label is here to serve. We’ll help you engineer custom safety labels that comply with standards and endure industrial conditions.