What Is A UL 969 Label?

UL 969 labels are labels that have been pre-tested and approved for use on various UL Listed and Recognized products to ensure critical safety information remains attached and legible. UL 969 labels are great for roll labels, waterproof labels, clear labels, GHS labels, and more. Do you need more detail? Let’s unpack this piece-by-piece.

What Does UL 969 Mean?

UL 969 is the reference to the UL/ANSI standard for Recognized Component Labels. The standard’s official name is UL 969 – Standard for Safety: Marking and Labeling Systems. Catchy, right? That’s why it’s usually shortened to just the standard number. Sometimes labels that comply with this standard are also called:

- UL Recognized Component Labels

- Durable UL Labels

- PGDQ2 Labels

- PGJI2 Labels

- CSA C22.2 No. 0.15 Labels

Why Should I Care About UL 969 Labels?

Before we go too much further, it’s important to understand why the UL 969 labeling and marking standard is such an important thing. At their core, UL and the other Nationally Recognized Testing Laboratories (NRTLs) are all about safety. Their logo on a complete product or component is supposed to indicate that the product has undergone and passed rigorous safety testing. So, if you view UL 969 labels from that safety directive, the picture comes into focus.

The Consumer’s View

For example, put yourself in the consumer/user’s view of things. Critical product information neatly fits into that mandate of safety. UL 969 compliant labels typically carry important safety information including warnings and technical information such as power requirements. You need to keep this important information with the product…for the life of the product (it won’t do you any good if it falls off 3-months after opening the box). This is why the UL 969 standard addresses all the things that potentially affect legibility including ink durability, ink fading, and the label’s ability to stick to the product itself.

The Manufacturer’s Side

From a manufacturer’s side, the UL 969 label requirements are about making compliance with UL’s safety directive easier (even if it may not always feel that way). We know that UL is requiring that certain safety information be present on a product or component and that it has to stay on that product and remain legible…otherwise, what’s the point? The challenge is that there are multitudes of different label solutions out there, each with different inks, different materials, and different adhesives. Without the right knowledge or consultant, it’s easy to select something that wouldn’t provide the lasting service you need. So, with this in mind, UL set about creating the UL969 standard to pretest and approved potential label solutions. This way the manufacturer, the consumer, and UL all know that the label will last and serve its safety goal.

How Do I Know If I Need UL 969 Labels For My Product?

The easiest way would be to consult your product procedure. This is the set of documents set up by UL or other NRTLs. These are proprietary to your company and are not publicly distributed.

If you don’t have access to your procedure documents, the next option would be to reference the standard itself. And in this case, this would be the standard under which you make your product. For example, UL 153 is the standard for Portable Electric Luminaires. Specifically, the Markings subsection is typically where they list the durability requirements. Using UL 153 as an example again, that particular standard contains this message under its marking section, “The marking and labeling system shall comply with the Standard for Marking and Labeling Systems, UL 969.”

The standard or company procedure are going to give you a definitive answer. If you don’t have those, your NRTL would be the next best resource. Absent of them, if it’s an existing label, take a look at the content. Typically, UL 969 certified labels usually have some of the following elements: safety information (Warning, Caution, Attention, etc.); or technical product information (50w, 750Hz, etc.). Any presence of this information on the label would likely indicate the requirement of UL 969 approved labels.

A Word on Nationally Recognized Testing Laboratories (NRTLs)

Let’s take a step back from UL 969 for a moment. I’ve mentioned NRTLs a few times. Why? Well just because the standard is called ANSI/UL 969, doesn’t mean that UL is the only group that references the UL 969 label requirements.

The Nationally Recognized Testing Laboratory (NRTL) Program is managed by the Occupational Safety & Health Administration (OSHA). OSHA was created by Congress with the mission of overseeing working conditions and training in the United States. The majority of OSHA’s regulations fall into the category of general requirements, so when it came to specific products, rather than regulate them directly, they decided to create the NRTL Program.

Under this program, OSHA approves private sector organizations to performs product certification. Yes, UL is the largest of these OSHA approved NRTLs, but there are many others, each with their own range (or scope) of products that they have been authorized to oversee. Depending on the product category, there may be multiple companies with overlapping scopes of approval. The end result is that the UL 969 label requirements are for more than just UL tested products. Testing companies such as ETL, IAPMO, and TUV require labels that meet the standard as well.

UL 969 Test Requirements, or What Makes a Label UL 969 Compliant?

Labels and markings produced under this standard are pre-qualified and tested by UL lab technicians to determine durability across a variety of environmental conditions. The certification steps roughly break out as follows:

- A label manufacturer would send a prospective label construction to UL

- UL would then perform a series of tests including weathering, humidity, heat, scratch, and adhesion tests.

- Complete label constructions that meet the standard are then certified to various conditions such as application surface (wood, polycarbonate, powder-coated metal, etc.), temperatures (e.g. -20 to 150 C), and exposure (e.g. occasional gasoline splash, indoor use only).

- Production of certified constructions are then evaluated annually by an onsite UL inspector as well as sent to the lab for testing.

It’s worth noting that printers are not allowed to freely substitute materials nor printing methods. This ensures the integrity of the complete label construction.

It’s important to note that complete label construction is the key phrase here. While individual materials and other components of a label can be individually tested under the UL 969 standard, those individual tests would fall under PGGU2—the Category Code Number (CCN) for components. This is a separate program (aimed specifically at the label manufacturing industry) that pretests individual parts of a label for eventual label use. The implication of this is that just because a material is UL 969 approved, does not mean that the complete label construction is UL 969 approved.

A UL 969 compliant label (essentially a label that would be used on a product) is all about the complete construction and how those individual components work together to create a cohesive final label. The components of a UL 969 approved label may include:

- Adhesive

- Facestock

- Ink

- Lamination

- Secondary Ink

It is the interaction and suitability of these components and how well they work together as a complete construction through the testing process mentioned above, which determines if a label is UL 969 approved.

Even then, do not forget about the performance categories. For example, application surface matters. If you have a UL 969 label that is approved for Stainless Steel only, but you are sticking it to polycarbonate—that label would not be approved for your specific application.

Category Code Numbers

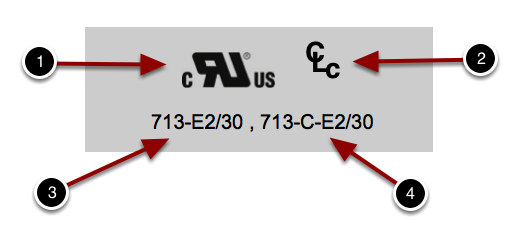

I briefly touched above on Category Code Number (CCN). Within the UL 969 standard, labels and markings are broken out into multiple categories. Sometimes specifications will reference these CCNs. The most common of these sub-categories are:

PGDQ2 – Marking and Labeling Systems for the United States

PGDQ8 – Marking and Labeling Systems for Canada

PGJI2 – Printing Materials for the United Stated

PGJI8 – Printing Materials for Canada

The only difference between PGDQ and PGJI are that labels that comply with the PGJI CCN are also approved for secondary printing, hence the name Printing Materials.

It’s also worth noting the US and Canadian standards aren’t harmonized, and so there are slight variations between the testing requirements for UL969 and CSA C22.2 No. 0.15 (969’s Canadian equivalent). This is why separate CCNs are necessary.

Secondary Printing

The PGJI CCN allows for secondary printing on UL 969 labels. This can be helpful for adding just-in-time information such as lot codes, date of manufacture, or even specific part numbers.

That said, again in the interest of long term legibility, there are rules. On these labels, you must use an approved ink system such as thermal transfer ribbon, laser toner, or hot stamping foil to add information to the label. Important to note, the method you use must be pre-approved to work with the complete construction just as any other component of the label. The file for each approved label construction will note what ink systems (e.g. thermal transfer inks) are approved for use.

As a side note, because it comes up frequently, hand-written pen, marker, or pencil is never approved by UL as a secondary printing ink system.

Core Labels Matter

At the end of the day, labels produced under the UL 969 standard are considered recognized components. Recognized Component are essentially verified pieces (or ingredients as it were) that are used to make up a final end-product. Since a Recognized Component isn’t made in the end-product facility, the only way to verify it meets the required specifications is some sort of marking. For the UL 969, that marking is a special label usually stuck on the inside core of the product.

Once you’ve placed on the inside core of a roll of labels, a UL inspector can verify the product for you. On the flip side, a lack of core identification is perhaps the biggest reason companies have production put on hold. Because if an inspector can’t verify that the labels meet the end-products requirements, the product doesn’t ship. So proper markings are as important as another element of UL 969 labels.

Do you still have questions? Our team of UL experts has experience with every step of the process from designing labels, to full runs, to those special projects that defy categorization. Let us help you build a compliant solution. Give us a call or request a proposal here.