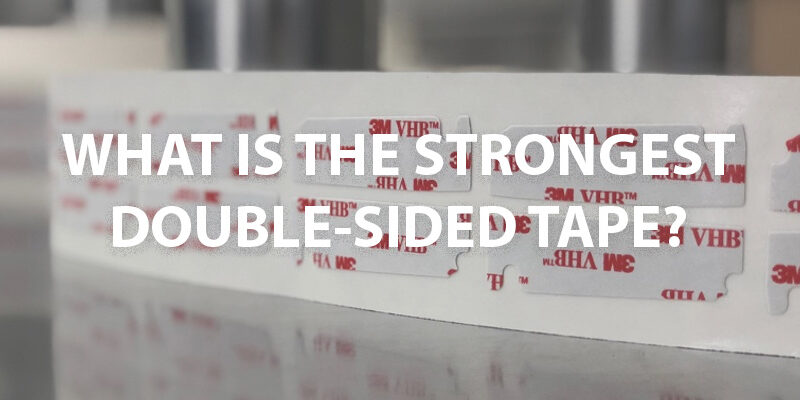

There are many double-sided tapes on the market, but which is the strongest double-sided tape and which is the best for industrial uses? With its endurance in extreme conditions and its versatility in bonding many different kinds of substrates, 3M VHB is one of the best double-sided tapes in use today.

As a 3M Select Converter, Coast Label can manufacture 3M VHB in any form you need. From rolls of 3M VHB to precisely cut shapes, we can get the exact product you need. Read on to learn more about one of the strongest double-sided tapes, 3M VHB.

UL Listed vs UL Certified Labels

What Is the Best 3M Double-Sided Tape?

3M is known for its innovation across many different product categories. From adhesives to medical supplies, 3M uses collaboration and creativity combined with science to produce high-quality products. 3M’s double-sided tapes are no different. If you’re wondering which of 3M’s double-sided tapes are the best, that answer is going to depend on what you need it for.

3M makes a variety of double-sided tapes that perform well under industrial conditions such as high temperatures. When you need a low profile, you might consider one of 3M’s thin-bonding tapes. These tapes are strong but thin, conforming to even irregular shapes. For bonds that need cushioning but don’t require extreme strength, consider one of 3M’s many double-sided foam tapes. But, if you need extreme strength and long-lasting hold, 3M VHB is your best bet.

What is 3M VHB Tape?

3M VHB is a permanent, double-sided tape that can replace many traditional fasteners. Since it hit the market in the 1980s, 3M VHB has been one of the best-performing double-sided tapes. VHB, which stands for Very High Bond, was one of the first of its kind and still outperforms other tapes on the market. Made from a closed-cell acrylic foam, 3M VHB’s secret weapon is its viscoelasticity. This means the tape acts both like a viscous liquid, filling in gaps and holes, and like an elastic solid, flexible but strong.

3M VHB comes in clear, black, gray, or white tapes of differing widths and thicknesses. VHB double-sided tape can also be configured to withstand various extremes. From exposure to solvents to heat cycling, there’s a VHB style that will work for you. If you’re trying to bond two dissimilar substrates, VHB can be customized with a different adhesive on each side of the tape. VHB can be engineered to bond to just about any surface, including low-surface energy plastics. VHB is not only one of the strongest tapes on the market but also one of the most customizable for your business.

3M VHB Specs:

- Surface temperature: Continuous up to 300°F. Intermittent up to 450°F.

- Application temperature: Apply in temps as low as 32°F.

- Waterproof: Yes.

- Weatherproof: Yes.

- Bond: HSE plastics, LSE plastics, metal, ceramic, glass, wood, brick, stone, etc.

- Irregular surface: Yes. VHB can be applied to surfaces that are not flat.

- Customizable: Yes.

- Shape: A converter can manufacture VHB in custom shapes to fit your needs.

3M VHB vs Gorilla Tape

When trying to find the best double-sided tape, you might wonder how Gorilla Tape stacks up against 3M VHB. Like VHB, Gorilla tape has adhesive on both sides so that it can be used to bond two different objects. Gorilla tape can be used both indoors and outdoors on wood, glass, brick, ceramic, stone, and some plastics.

Unlike 3M VHB, however, Gorilla Tape won’t bond well with low surface energy plastics such as polyethylene and polypropylene plastics. Gorilla Tape can hold up to 30 pounds and can be applied in temperatures as low as 50°F. Like VHB, Gorilla Tape is clear and won’t yellow over time.

Gorilla Tape Specs:

- Surface temperature: Continuous up to 194°F. Intermittent up to 302°F.

- Application temperature: Apply in temps as low as 50°F.

- Waterproof: Yes

- Weatherproof: Yes

- Bond: HSE plastics, wood, glass, ceramic, stone, etc. Does not bond with LSE plastics.

- Irregular surface: No, must be applied to flat surfaces. Can bond to a textured surface, but the hold won’t be as strong.

- Customizable: No.

- Shape: Comes in rolls or squares.

Why You Should Use 3M VHB Tape

If you’ve never used 3M VHB tape before, you might be wondering why you should make the switch. Traditional fasteners have probably been working just fine for you, and you might doubt that an adhesive tape can work as well. But 3M VHB is more than just a double-sided tape: it’s an easier way of doing things.

- 3M VHB is quick and easy to apply. There’s no need for drilling holes or welding objects together. Application is as simple as applying the tape and connecting the pieces together.

- You can save money. Traditional fasteners can be pricey and require lots of storage to keep track of all the different parts you need. 3M VHB is extremely affordable and can replace most kinds of fasteners.

- The versatility of VHB means that you can use it on a variety of different projects, with no need to keep large stocks of various fasteners around.

Benefits of 3M Double-Sided Tape

3M VHB double-sided tape is a product that has stood the test of time. It’s trusted in many industries to stand up to tough conditions. As one of the best double-sided tapes on the market, you can trust 3M VHB to work hard and hold strong. 3M VHB makes mounting, assembling, and repairing quick and easy. Here are just some of 3M VHB’s many benefits:

- Faster assembly time

- Design flexibility

- Immediate handling strength

- Bond dissimilar materials

- Bond low surface energy plastics

- Clean aesthetic

- Less bulky than traditional fasteners

- Lightweight

- Provides a smooth finish

- Prevents intrusion of moisture

- Gap filling between substrates

- Vibration damping

- Accommodates different rates of thermal expansion

- Lasts for years

- Permanent bond

- Can handle both static and dynamic loads

- Performs well in extreme temperatures

- Virtually invisible when applied

Uses of 3M Double-Sided Tape

When we say that 3M VHB tape can be used to replace almost any kind of fastener, we mean it. As one of the strongest double-sided tapes, VHB is incredibly versatile as well as durable. With no need to drill holes, weld joints, or handle messy glue, 3M VHB makes construction and repairs so much easier. Here are just some of the many uses of 3M VHB tape across several different industries:

- Transportation: Attach glass windows, assemble panel trailers, bond panels to roof bows, bond aluminum panels to ambulance frames, among many other things. The durability and ability to bond dissimilar materials makes 3M VHB one of the best double-sided tapes for this purpose. In fact, in one test 3M performed building a semi-truck with VHB, the tape bonds outlasted parts that were welded and mechanically fastened.

- Construction: Attach trim, extrusions, moldings, kickplates, stiffeners, etc. 3M VHB is particularly useful in construction for its ability to attach to a variety of building materials. Prominent buildings using VHB in parts of their construction include the Singapore Treasury Building, the Walt Disney Concert Hall in LA, and the Chicago O’Hare airport.

- Metalworking: Connect a variety of metal substrates, even those with a powder coat or painted surface.

- Appliance building: Assemble dishwashers, washers, dryers, refrigerators, etc. 3M VHB is resistant to moisture and can dampen vibrations, making it perfect for this use.

- Electronics: Use 3M VHB to bond parts in consumer electronics and provide protection from impact as well as moisture resistance.

- Signage: Mount pictures, signs, and art with 3M VHB for a sturdy hold without the use of nails, screws, and anchors.

How to Apply 3M VHB

One of the best things about 3M VHB is how easy it is to apply, especially compared to other mounting and fastening hardware. Pretty much all you have to do is place the tape and you’re good to go. However, we do have few tips for ensuring the best application of your 3M VHB double-sided tape.

- Step one: Prepare the surface. For most surfaces, that means wiping it down with a solvent. Remove all oils and grease, which can prevent adhesion. Some very textured surfaces, such as wood, may require a sealant. A silane treatment is useful for applications to glass surfaces. For plastics and painted surfaces, you may want to abrade with a fine grit. Finally, make sure the surface is dry.

- Step two: Apply the tape. There are a number of effective ways to apply 3M VHB. Probably the most common is hand application. Apply at an angle with constant pressure and cut. You can use a file cleaner to rub the edge of the protective liner for easy removal. A hand tape applicator or a push-through laminator are both easy tools you can use to apply the 3M VHB tape with more precision.

- Step four: Apply pressure across the width of the tape for best adhesion. This will allow the VHB to ooze into any gaps and cracks.

Although VHB will hold firmly after being applied, the adhesive actually gains strength over time. It’s best to wait at least 24 hours before putting weight on the tape. It takes 72 hours for the adhesive to reach its full strength. So if you’re mounting a hook or other object that will take the weight, make sure you let the adhesive cure before placing weight on it.

How to Remove 3M VHB

3M VHB is designed to bond permanently, so once it has been applied, it’s not easy to remove. However, sometimes mistakes happen or changes need to be made. Here are a few tips on how to remove 3M VHB:

- One of the first things you’ll need to do is break the bond between the tape and the substrate. 3M has some tools you can use to help you break the bond and remove all of the tape–the Smart Tool or the Stripe Off Wheel. You can also use dental floss to saw through the adhesive and break the bond.

- If you are able to peel the tape off, do it slowly and at an angle. This will help you remove the tape as completely as possible.

- If there is residue left behind, you can use WD-40, Goo Gone, or a mix of warm water and lemon oil to buff the residue off with a cloth.

- You can use acetone to remove residue from glass.

- You may need to soak the residue with your chosen solvent to remove it completely.

- In some cases, you may be able to apply a strong masking tape over the residue and lift it off with the tape.

Storing 3M VHB

VHB can be stored at between 40°F and 100°F and a relative humidity of 0-95%, but the optimal conditions to store 3M VHB are at 72°F with 50% humidity. This will ensure the integrity of the tape remains intact. 3M warrants the tape for 24 months from the date of manufacture and suggests using it before the 24 months is up. According to 3M, however, the tape will likely still perform as expected even after the expiration date.

3M VHB from Coast Label

3M VHB is truly one of the strongest double-sided tapes on the market. From its resistance to extreme conditions to its durability, VHB is a product that does it all. Replace rivets, welds, screws, bolts, and other kinds of mechanical fasteners all with one product. If you’re ready to make the switch from traditional fasteners to 3M VHB, Coast Label is here to help.

As a 3M Select Converter, we can custom convert 3M VHB to your specific projects. Whether you need custom shapes or different adhesives on each side of the tape, we can engineer VHB to your unique needs. Our specially trained application specialists will work with you at every step of the process to ensure you get exactly what you need. We can make custom stickers and labels for you! Whether you need custom security labels or direct thermal labels, we can make them for you! Contact Coast Label today for a free proposal!