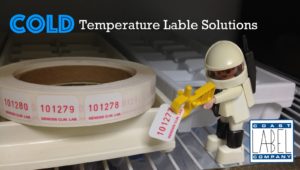

EXTREME TEMPERATURE COLD TEMP LABELS & TAGS

The Application of Extreme Temperature Labels & Cold Temp Labels

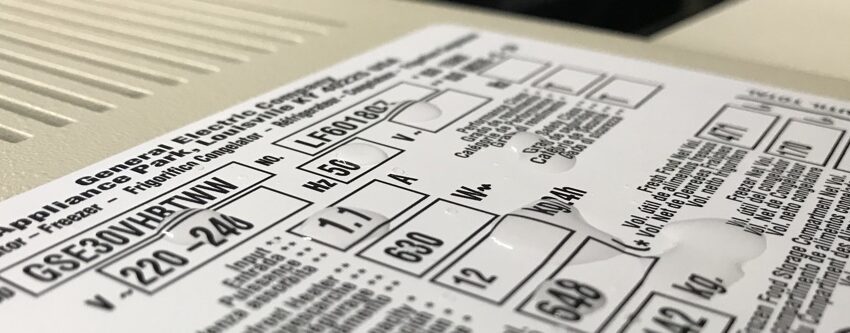

If you require a label that can be applied and will adhere in extremely low temperatures, cold temp labels are the solution. Common uses include clinical specimen labeling; pharmaceuticals; identification for the preservation of perishable items; food storage; and industrial applications where products must have labels applied outdoors during cold winter conditions.

At Coast Label our extreme temperature labels can be applied to a broad range of clean surfaces. Whether you have a standard label application or a unique problem that requires a custom solution, we will work with you to design a cold temperature label that will meet your needs. Our Application Specialists are experts in selecting the right adhesive for your cold temperature application–a critical component for this type of label.

Extreme Temperature Label Capabilities:

- Moisture resistant materials

- Direct thermal

- Thermal transfer

- Custom shapes

- Tight mandril labels

Cold Temp Labels

Unregulated temperature changes, as well as cold warehouse settings, have a tendency to expose packages to an expansive fluctuation of hot and cold environments. Shipping facilities and loading docs make for unreliable temperatures when it comes to applying labels. Depending on the adhesive, these less than desirable circumstances can lead to the breakdown or malfunction of your product labels. Becoming hard and brittle, labels tend to lose their tacky quality. It may not become immediately obvious, but there’s a good chance the label will fall off at some point down the road.

When cold or low-temperature labels are needed, this calls specifically for thermal labels that are manufactured for extremely cold environments. Frost and moisture as well as cold and dry applications need to be considered. We can help you determine which freezer-grade labels are the best fit for your labeling needs.

Extreme Temperature Labels

High-temperature labels or heatproof stickers are labels that are designed to withstand temperatures up to 730 degrees Fahrenheit. Not only can they take the heat, but they are resistant to chemical and solvent washes, reflow and infrared overs, ultrasonic cleanings, and more. Some label materials are able to resist high temps for long periods of time while others for only short bursts of time. The longevity of the label will depend largely on the material they are printed on.

We can make them any size, shape, and color you want in a wide range of finishes such as gloss, satin, or matte. Our team of dedicated label specialists is always available to guide you through the process step by step.

Low Temperature Label Uses

Low temperature labels are specifically designed to withstand extremely low temperatures without being damaged or losing their adhesion. Typical labels tend to peel or fall off in extreme cold environments, so a stronger adhesive is used for low temperatures. These labels are commonly used in environments where temperature fluctuations or freezing conditions are present. Here are some of the most common uses of low temperature labels:

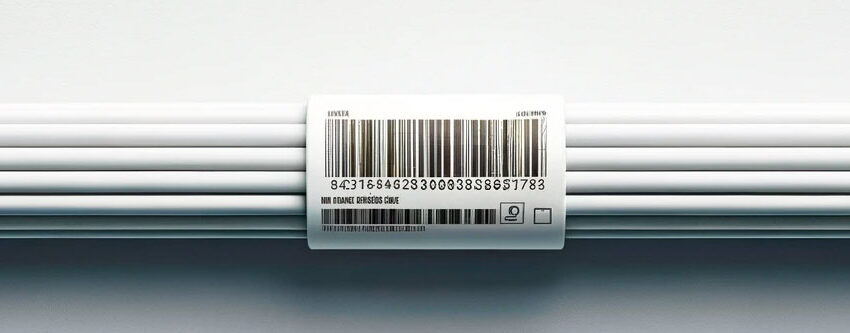

- Food and beverage industry: Low temperature labels are widely used in the food and beverage industry, especially in refrigerated or frozen storage areas. They can be applied to packaging, containers, and even directly on food products. These labels provide crucial information such as expiration dates, barcodes, nutritional facts, and product branding, which remain readable and intact in cold environments.

- Cold storage facilities: Labels used in cold storage facilities need to endure extreme sub-zero temperatures. They are essential for organizing inventory, tracking items, and ensuring accurate stock management. Low temperature labels can be applied to storage racks, pallets, and boxes even in freezing conditions.

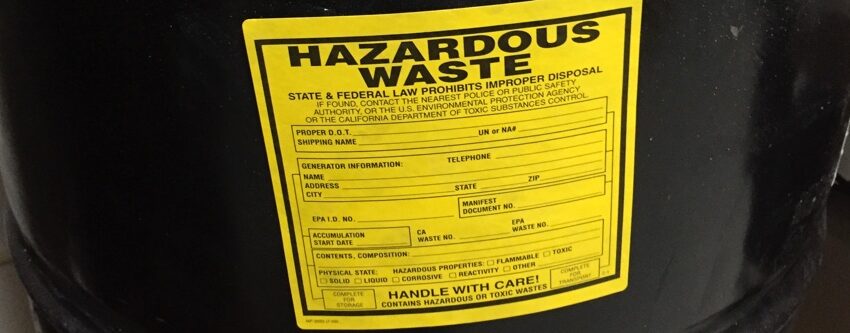

- Pharmaceuticals and healthcare: Extreme temperature labels play a vital role in the pharmaceutical and healthcare industries, particularly for the storage and tracking of temperature-sensitive medications and vaccines. These labels help ensure proper inventory management, prevent errors, and maintain critical information such as batch numbers, dosage instructions, and expiration dates throughout the cold chain.

- Laboratories and research facilities: Laboratories often require labels that can withstand freezing temperatures for the storage of biological samples, reagents, and chemicals. Low temperature labels are crucial for maintaining accurate sample identification, minimizing errors, and preserving sample integrity.

- Outdoor applications: In some cases, labels may need to withstand cold temperatures due to outdoor exposure. For example, in the logistics and shipping industry, low temperature labels can be applied to packages, containers, or vehicles that may be exposed to harsh winter conditions. These labels ensure that important shipping info, tracking numbers, and barcodes remain intact.

Cold Temp Tag Uses

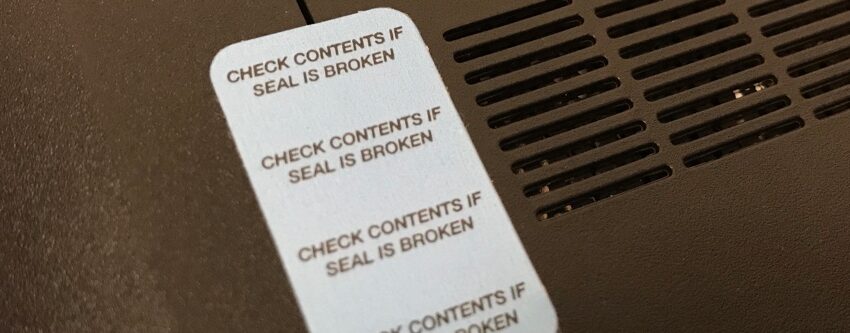

Similar to low temperature labels, cold temp tags are specifically designed to withstand low temperatures without losing functionality. While low temperature labels are backed by adhesive, cold temp tags are designed with a hole or attachment mechanism so they can be hung or attached to objects. Here are some of the most common uses of cold temp tags:

- Inventory and asset tracking: Cold temp tags are widely used for inventory and asset tracking in cold storage facilities, warehouses, and other environments with low temperatures. These tags can be attached to containers, equipment, tools, or machinery to ensure accurate tracking, organization, and identification, even in freezing temps.

- Equipment maintenance: Cold temp tags are useful for tracking maintenance schedules and inspections of equipment in cold environments. These tags allow maintenance personnel to easily record information about inspections, repairs, and service dates.

- Safety and warning labels: Cold temp tags can be used for safety and warning purposes in environments where low temps pose hazards. These tags can be attached to pipes, valves, electrical panels, or other equipment to provide warnings about dangerous conditions.

- Quality control and testing: Cold temp tags play a vital role in quality control processes for products that need to be stored or tested in low temperatures. These tags can be attached to samples, containers, or test equipment to indicate temperature sensitive items and ensure compliance with temperature requirements.

- Outdoor activities and sports: Cold temp tags can also be used in outdoor activities where extreme weather conditions are present. For example, these tags can be attached to clothing, gear, or equipment used for skiing, snowboarding, or mountaineering and provide identification, emergency contact information, or safety instructions.

When Not To Use Them

While low temperature labels and cold temp tags are designed to be durable through extreme conditions, there are some situations where they may not be suitable. Here are some instances when you may not want to use low temperature labels and tags:

- High temperatures: Although low temperature labels are designed for durability, they are not intended for use in extreme heat. Exposure to heat can cause the labels to deteriorate, lose adhesion, or become unreadable.

- Moist and humid environments: Low temperature labels are resistant to cold temperatures, but certain materials and adhesives designed for low temps may not function when exposed to moisture. In these situations, it’s important to make sure the adhesive and material are appropriate for humid and moist conditions. For example, hot-melt rubber adhesive performs well in low temperatures where moisture is present.

- Chemical exposure: Low temperature labels may not be compatible with certain chemicals and solvents, which can cause them to deteriorate. If your application involves chemical and solvent exposure, talk with one of our application specialists about chemical-resistant labels.

- UV exposure: Low temperature labels are not resistant to UV exposure. Prolonged exposure to sunlight can cause them to fade or become illegible.

How Do Freezer-Resistant Labels Work?

Freezer-resistant labels are specifically designed to endure the extreme conditions inside a freezer. But how do they work? Typical adhesives lose their tacky quality in freezing cold temps, but freezer-resistant labels use a strong adhesive that is designed to maintain its bond even in freezing temps. Since moisture is often present in freezers, a moisture-resistant adhesive such as hot-melt rubber adhesive is often used.

In addition to the adhesive, freezer-resistant labels also typically require the use of special materials that can withstand low temperatures. Certain materials become brittle when exposed to low temperatures, so it’s important to choose a material that will remain flexible. Common materials used for freezer applications include vinyl, polyester, or synthetic paper.

Another concern when it comes to freezing temps is the durability of the ink. Choosing inks and toners that are resistant to cold temperatures is key to maintaining the legibility of barcodes, text, and graphics. Some freezer-resistant labels also use a protective coating to ensure the legibility of the label and text.

Cold Resistant Labels vs Standard Tape

Standard tape is meant to be used at room temperature. It’s neither cold resistant nor heat proof and will not perform in extreme conditions. When exposed to extreme heat or cold, the adhesive will lose its bond with the surface and peel or fall off.

Similarly, packing tape is not designed for low temperature applications. This kind of tape uses an adhesive that is viscoelastic–in order words, it has properties of both a solid and a liquid. Because of its viscoelasticity, the adhesive becomes brittle when exposed to low temperatures and will not stick.

Cold resistant labels, on the other hand, are designed with low temperatures in mind. Because cold resistant labels use a stronger adhesive, they are able to stay put in extreme cold when standard tape would fail.

What Are the Best Surfaces for Low Temperature Labels?

Extreme temperature labels work on a variety of surfaces, such as glass, plastic, foil, and metal. Some surfaces–like highly textured materials or low surface energy plastics–may pose a challenge for application. Our application specialists can help you engineer the perfect label for your low temperature applications.

How to Label Freezer Containers

Labeling freezer containers is an important step in maintaining and organizing your freezer storage. Before labeling your containers, you’ll want to make sure you properly clean the surface your labels will be applied to. Dirt and dust on the surface of your container can prevent proper application. Once the surface is dry, choose a spot that is both visible and accessible to place the label. Align the label, peel the backing off carefully, and press the label smoothly and firmly in place.

HELPFUL LINKS

I like the personal contact that Coast Label provides. Every time I call I know I can talk with [people], who know me and my requirements. Medical equipment labels are very complex; Coast Label’s ISO 9001 Quality Certification is very important to my clients.