QUALITY CONTROL STICKERS / QUALITY ASSURANCE LABELS

What do Quality Control Labels do?

Quality control labels are important components of a well functioning system. But experience has taught us that they only work if designed right. Consider the following:

- Are they only in place during the manufacturing process? You may want a removable adhesive that peels off cleanly at the end of the process.

- Trying to prevent a calibration from being moved? You may want a tamper-evident construction.

- Are their notes being added in the field? A material that accepts the type of markers or pens being used in the field is critical.

Let us consult with you to help design the right label–one designed to work within your system–can make compliance and quality control efforts easier. Below are just some of the many systems we have manufactured product for:

- Verify tools, equipment, and machinery have been properly calibrated

- Tag incoming and outgoing product

- Mark shipments as RoHS or Lead-Free Compliant

Capabilities of Quality Control Labels:

- Waterproof materials

- Scuff resistant markings

- High visibility materials

- Accepting of handwriting

- Tamper evident materials

Quality Control Stickers & Labels

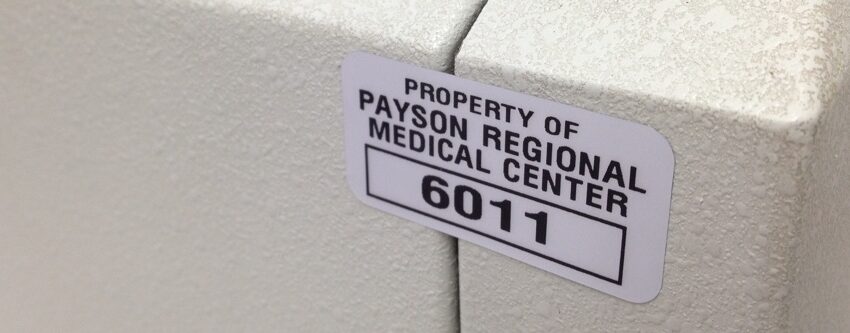

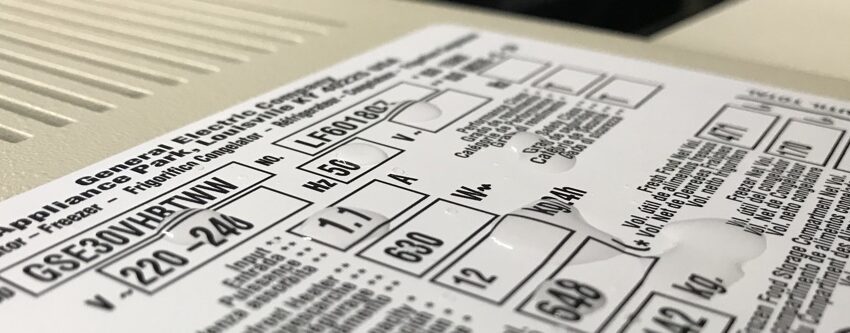

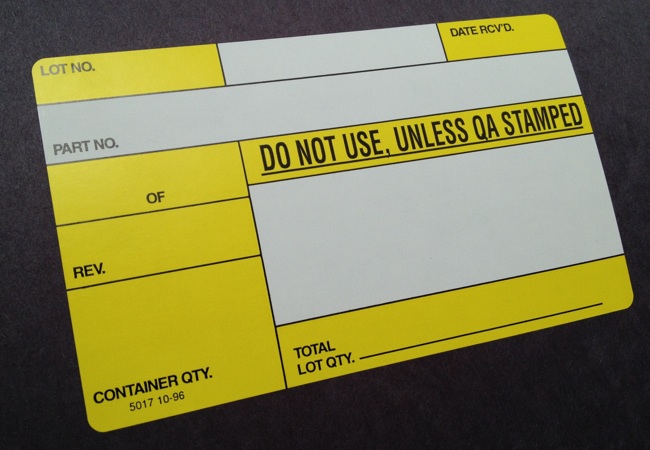

Quality control stickers are a clear indicator that your product has passed quality-control tests. Finding the right quality control labels will ensure that products and services meet both delivery and production requirements. The proper labels will clearly show a rejection or an acceptance of materials, goods, and operating equipment. Quality assurance labels aid in documenting dated inventory, equipment, instruments, charts, and other materials.

Our quality control labels are available in a variety of sizes, colors, and adhesives to best suit your needs. If we don’t have a stock label you like, we are more than happy to collaborate with you on creating a specific label for your application.

Quality Assurance Labels

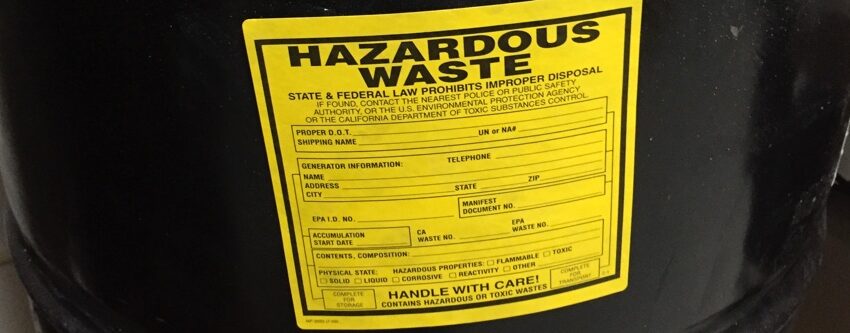

Quality assurance labels play a crucial role in ensuring product integrity and consumer confidence. These labels serve as a mark of trust, assuring your customers that a product has undergone rigorous testing and meets stringent quality standards. Whether it’s indicating compliance with industry regulations, certifying product authenticity, or demonstrating adherence to safety protocols, quality assurance labels provide valuable information to consumers.

These labels not only instill confidence in the product but also enhance brand reputation and differentiate it from competitors. From food and beverages to electronics and pharmaceuticals, quality assurance labels act as a tangible testament to a company’s commitment to excellence, assuring customers of the reliability and superior quality of their chosen products.

Quality Assurance Label Uses

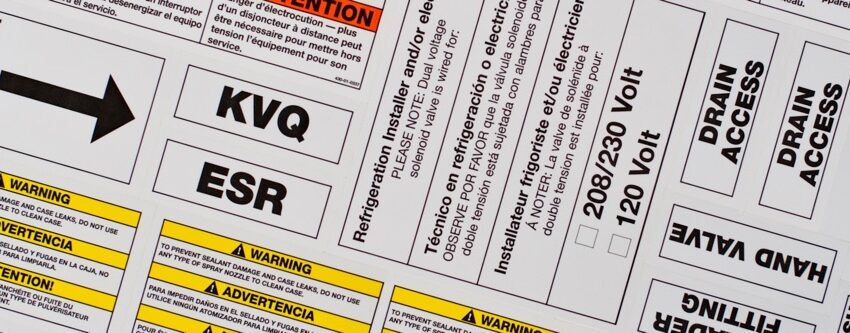

1. Compliance

Quality assurance labels are used to indicate that your product meets specific regulatory or industry standards. They provide assurance to your customers that the product has undergone testing and conforms to safety, quality, and environmental requirements. Examples include labels indicating compliance with FDA regulations for food and pharmaceutical products or certifications for electrical safety standards.

2. Authenticity

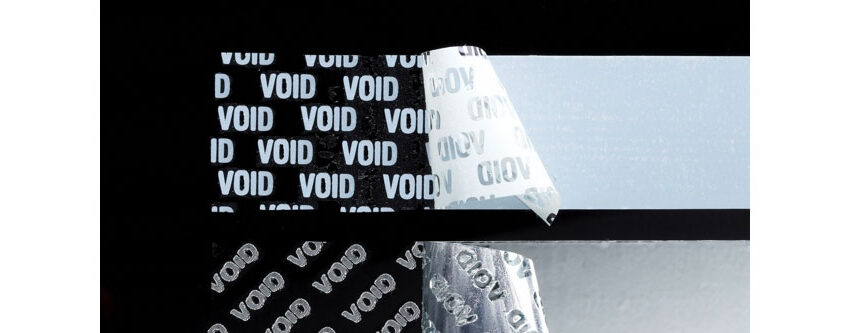

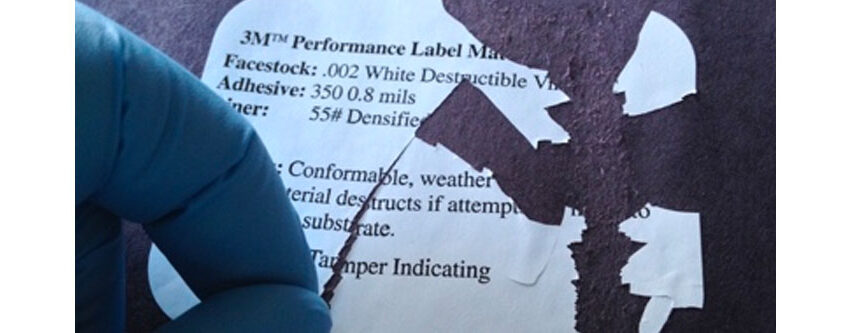

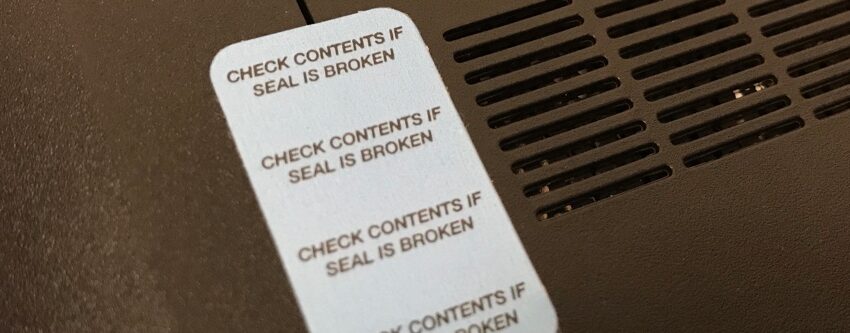

Quality assurance labels are employed to verify the authenticity and origin of a product. They may include unique codes, holograms, or tamper-evident features to ensure that the product is genuine and not counterfeit. These labels are commonly used in industries such as luxury goods, electronics, and automotive to combat counterfeit products and protect brand reputation.

3. Quality Certification

You can utilize these labels to signify that your product has met specific quality criteria or has been certified by an authorized body. These labels indicate that the product has undergone thorough testing and inspection, ensuring its reliability, durability, and overall quality. Examples include ISO certifications, UL labels for electrical safety, or certifications for organic and sustainable products.

4. Traceability

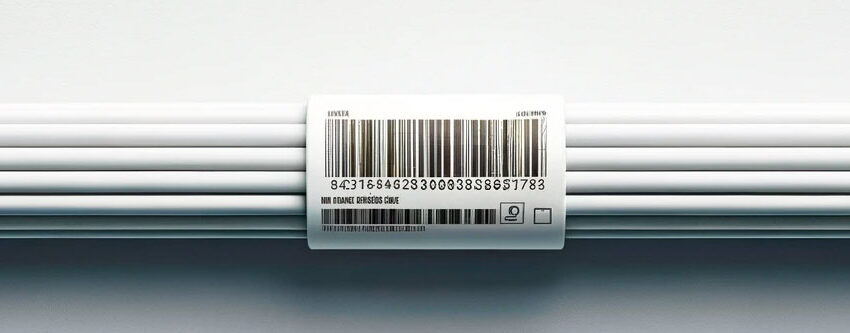

Quality assurance labels are used to enable traceability throughout the supply chain. They can include barcodes or QR codes that provide detailed information about the product’s origin, manufacturing process, and components. This allows for efficient product recalls, quality control, and the ability to track and address any issues that may arise.

5. Product Differentiation

These labels can be utilized to differentiate your product from those of your competitors. By prominently displaying labels that indicate superior quality, safety features, or certifications, companies can build trust with consumers and establish their products as premium options. These labels help consumers make informed choices and create a positive perception of the brand.

How to Choose Quality Control Stickers and Labels

When designing your quality control stickers and labels, you’ll want to take into consideration a number of factors:

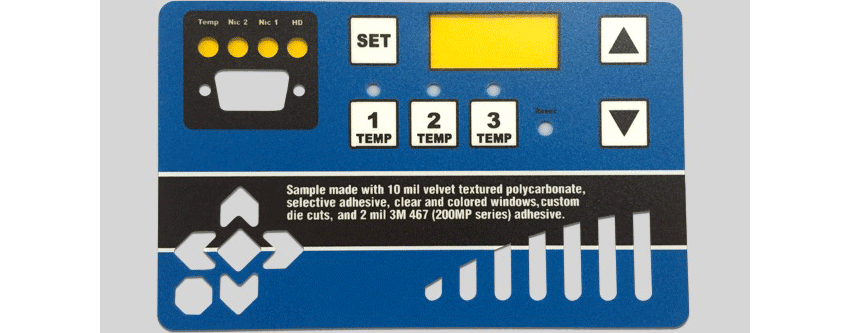

- Size: The right size can make all the difference. Too small, and the labels will be difficult to see. Quality control labels should be big enough to be legible and easily visible.

- Durability: Different conditions require different levels of durability. For example, if your labels will be exposed to heat, you’ll need to choose heat resistant materials. Labels exposed to moisture, UV light, or chemicals will all require a more durable label than labels in a temperature-controlled facility.

- Adhesive: Another factor to consider when choosing your quality control stickers is the application site. Some materials present challenges for adhesion. For example, Low Surface Energy (LSE) plastics are more difficult for adhesives to bond with. Choosing the right adhesive will ensure that your quality control stickers and labels stay put. Additionally, the amount of time you need your stickers to stay in place will affect the kind of adhesive used. Temporary quality control stickers will need a removable adhesive.

- Security features: If tampering is a concern, quality control stickers with tamper-proof qualities can make all the difference. Choose from void-pattern labels, destructible vinyl, and more to ensure that only authorized users access your equipment.

Types of Quality Control Labels

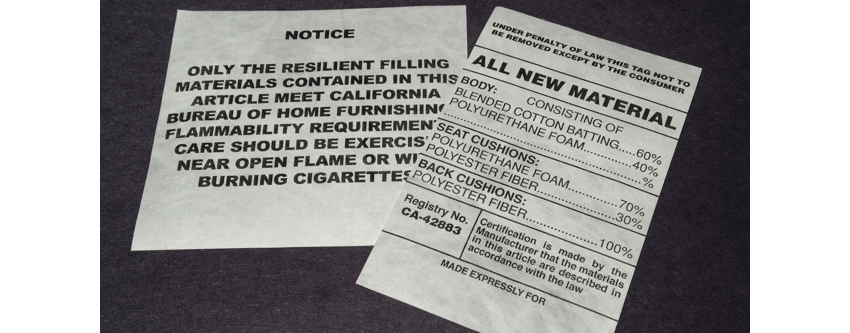

From manufacturing to healthcare, quality controls labels and stickers are used across many industries. Quality control labels help ensure that raw materials, finished goods, and equipment meet certain specifications. Some of the most common types of quality control labels include:

- Machine calibration labels

- Inspection labels

- Service and maintenance logs

- Pass/fail stickers

- Shelf life labels

- Tamper-evident labels

- Write-on inventory labels

- Color-coded labels

How Quality Control Labels Benefit Your Business

Quality control labels–used as part of your quality control system–have a number of benefits. Here are some of the ways quality control labels can benefit your business:

- Safety: One of the most important benefits of quality control labels is safety. Using quality control labels helps you ensure that products and machinery are safe for use, as well as indicate which ones are not.

- Sort products: Quality control labels help you easily sort accepted and rejected products. With just a glance at the label, employees know the status of the product. This in turn helps you prevent faulty products from reaching the market.

- Keep track of service dates: Maintenance and calibration of your equipment is essential to its longevity. Quality control labels with write-on capabilities let you log dates of service so you know when maintenance is due.

- Improve efficiency: With quality control labels, inspectors can quickly indicate pass/fail status of products and materials, mark important dates, etc., for a more efficient inspection.

- Tamper-proofing: Tamper-proof quality control labels indicate when machinery and equipment have been tampered with. This protects you and your employees from using possibly unsafe equipment.

Quality, regulatory, engineering, marketing, branding, sales, order processing, fulfillment, supply chain management—all of those things are important in this business. When I look for a vendor I am looking for somebody that can understand all those other elements as well. Coast Label does a great job of understanding and fulfilling those requirements.